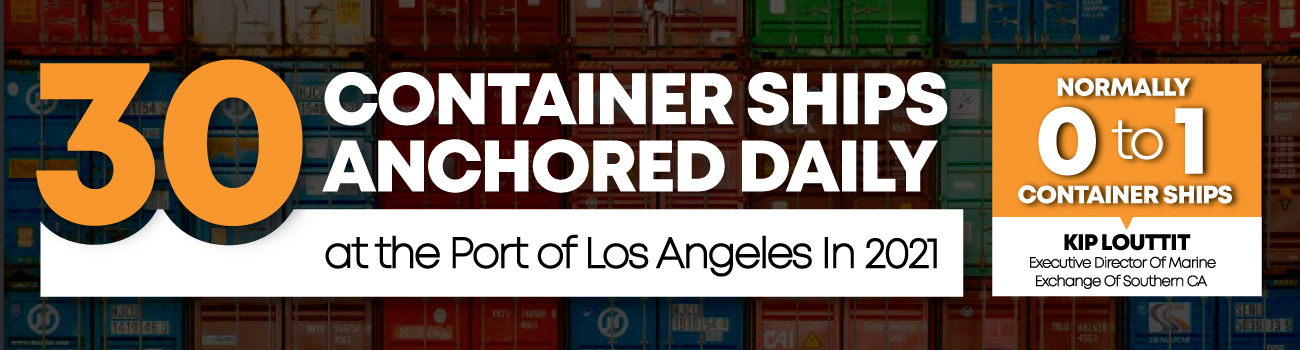

An average of 30 container ships are being anchored daily just off the coast near the Port of Los Angeles this year. According to the executive director of Marine Exchange of Southern California, Kip Louttit, the normal number of container ships at anchor is usually zero to one. This is all part of a bottleneck in the supply chain that is still straining not just the LA port but also the neighboring ports which handles about a 3rd of all national imports in the US.

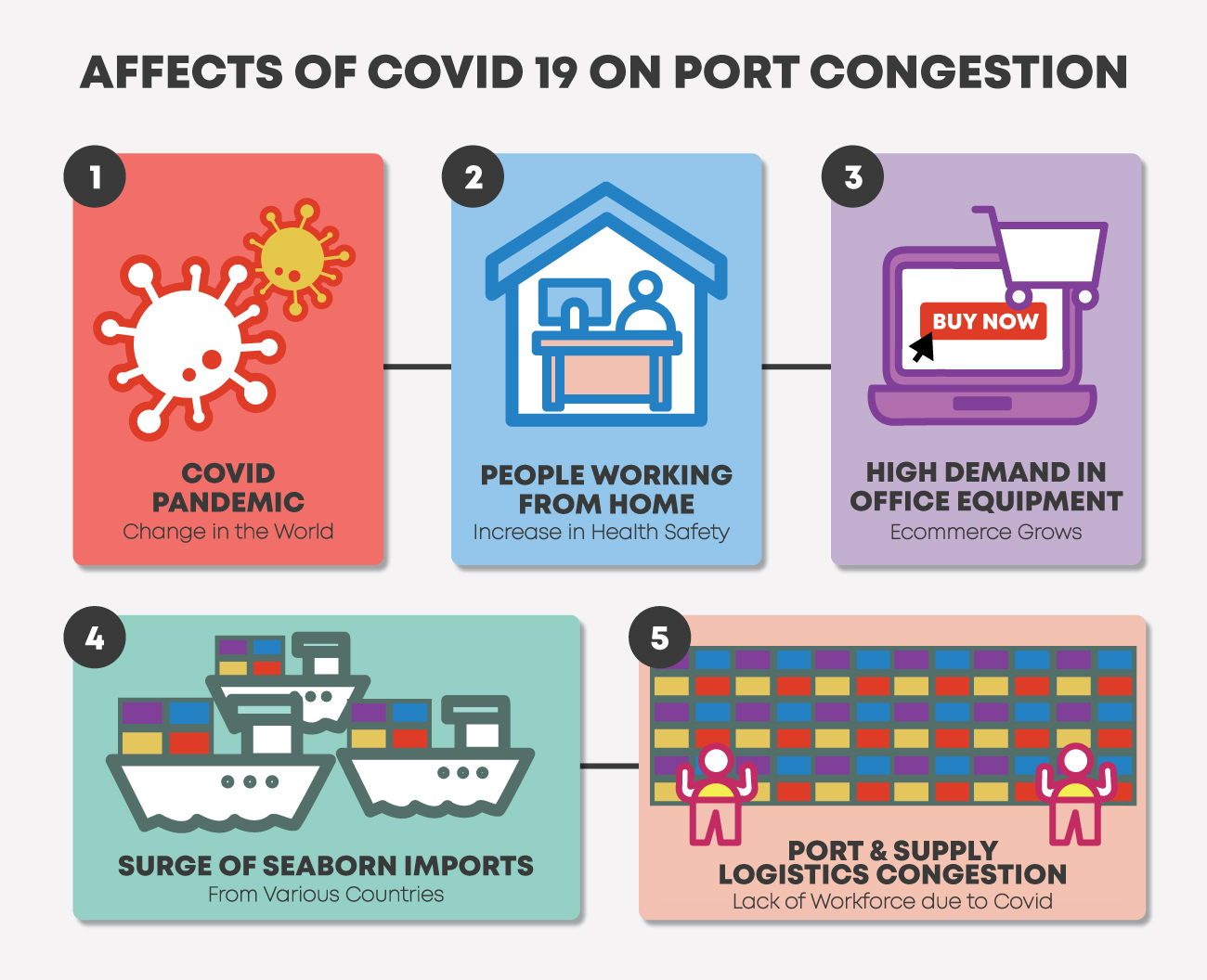

Experts say that one of the reasons causing this backup started with Covid-19. The new “work from home” model has caused a roaring demand for consumer goods. Most of which aren’t made in the US. Therefore seaborn imports to the US started surging in the late summer as manufacturers and retailers tried to rebuild inventories that were sold by shoppers in the early months of the pandemic.

According to Louttit, there were 57 extra ships that arrived in the fall of 2020, far above normal levels which created a bottleneck in the import system. Simultaneously the land-based movement system (trains, trucks, terminals, warehouses, and forklift drivers) had a fraction of the workforce out due to Covid-19 further creating a jam in import operations. There’s more cargo with a less efficient way of moving the goods ashore which caused a massive backup of ships being anchored across the port.

But this hasn’t stopped shipments from continuing the surge. In February 2020 there was a surge of over 177 ships carrying over 800,000 containers that arrived at the LA and Long Beach Ports. According to the Marine Exchange of Southern California that was an increase of 31% more ships and 49% more containers in comparison to the same month last year. On average ships have to wait approximately 7-8 days before they reach the port to have goods unloaded which means that consumers are waiting too.

According to Bloomberg news, companies like Tesla, Sony, and even Crocs the shoe company have expressed concerns on supply-chain congestion stating they cannot meet demand during the next few quarters. Experts are expecting the limited supply of products to be resolved well by the end of 2021.

The congestion has fueled the demand for shipping which means the cost of shipping and importing has gone up drastically during the pandemic. According to S&P Global Platts the current global average shipping rate is nearly 4x as much as it was back in January 2020. In March 2021 a 40-Foot container costs $4,500 compared to January 2020 which was only $1,200 per 40-Foot container.

At the ports, their short-term strategy to get the ships moving again is to vaccinate workers, maximize efficiencies, and asking importers to increase the speed at which they pick up cargo. Their hope is that it will help clear the backlog of ships by this summer before peak season comes into play around August. With the reopening experts hope that the demand for shipping will drop off quickly to help alleviate port congestion.

Sources:

https://www.bloomberg.com/news/newsletters/2021-04-29/supply-chains-latest-shipping-delays-to-restrict-firms-all-year

https://www.freightwaves.com/news/inside-californias-colossal-container-ship-traffic-jam

https://www.spglobal.com/platts/en