We’re here to tell you that tape is certainly not just tape when it comes to being a responsible brand leader in the industry. But we also don’t expect you to be the expert on packaging tapes, what’s hot, and what’s not – that’s our job. As innovators and customization experts in the packaging sealing business, we can tell you that the sustainability and recyclability of packaging products are a top priority in our industry.

In the most general of terms, packaging tape can be recycled. However, some are more easily recycled than others. The majority of recycling centers will accept cardboard and paper with tape attached; it just depends on their process and their equipment. While paper tape is the easiest to recycle and the kindest to the environment, there are tapes made from paper that are not as kind due to the other materials used alongside it in the tape’s makeup. The real sticky stuff that has PVC or polypropylene in it can jam up a processing machine if there’s too much of it. There are a lot of developments in more recyclable tapes for our industry – like cellulose tape and tapes made with plant starch – but whether they will become mainstream in the packaging industry remains to be seen at this point.

So, we feel it’s our duty to let you know what your best (green) options are when choosing a packaging product. First, there’s a bit of industry speak to cover. At BestPack, we follow best practices in environmental standards like the ISO 14001 environmental standard, which is “an internationally agreed standard that sets out the requirements for an environmental management system”. We also look at the RoHS information for each and every one of our products. Sometimes called the “lead-free directive”, the Restriction of Hazardous Substances (RoHS) Directive restricts how ten hazardous materials are being used in the manufacturing of certain products.

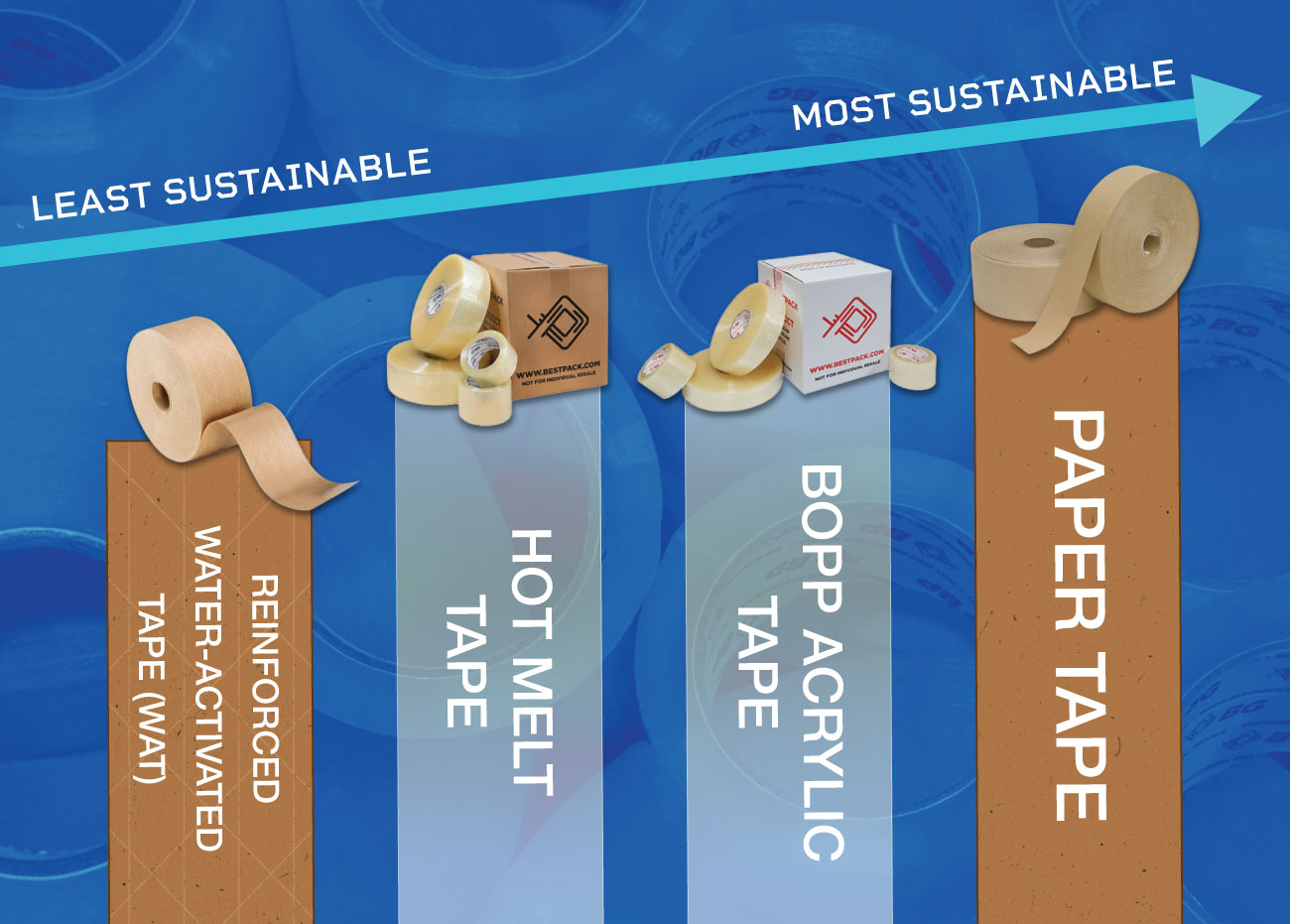

Let’s look at 4 of the most commonly used package sealing tapes, in order of recyclability and sustainability. We’ll provide a brief overview here covering the basics, but look for expanded articles on our blog on each of these tape types, in more depth.

What’s it made of? Made from natural kraft paper with a resin treatment that makes it very durable in all weather, plus it’s moisture-proof.

How is it used? It is an ideal general-purpose tape used for sealing medium and lightweight cardboard boxes.

Is it environmentally friendly? Yes, very. It’s recyclable and biodegradable and 54% of it is made of a biobase natural rubber adhesive. You could literally shred the materials and put them directly in the earth to compost over time.

What’s it made of? Not all acrylic tape is equal. BestPack’s is made from a low elongation film with an acrylic adhesive… Biaxially Oriented Polypropylene (BOPP) is a thermoplastic polymer that is malleable at certain specific temperatures and returns to a solid form when it cools down.

How is it used? It can be used in both hot & cold temperatures and is a freezer-grade tape perfect for cold temperature applications, like food packaging operations and long-term sealing.

Is it environmentally friendly? After some processing, yes. Boxes using BOPP are actually boiled which separates the tape from the box so that the cardboard can be recycled. The plastic from the tape floats to the surface and is recycled separately. The acrylic adhesive on the tape is water-based so it dissipates as it’s boiled.

What’s it made of? It’s a BOPP low elongation film with a hot melt adhesive. Characteristics that make it unique are its quick tack and high shear.

How is it used? For consistent manual or automated sealing applications. Depending on the thickness of the tape it can be used for light or heavy-duty applications. This includes machine-applied tapes and overstuffed cartons.

Is it environmentally friendly? Well, it depends. Most hot melt tapes use a petroleum-based adhesive and wax (paraffin) to achieve that quick tack that the tape is known for. These ingredients are not necessarily kind to the environment. But, through a re-pulping process, the hot melt adhesive can be removed and separated from the BOPP film and the box it’s used on so that the individual parts can be appropriately recycled.

What’s it made of? It is a paper-backed tape with a water-based adhesive front that is stronger than plastic because of the synthetic fibers sandwiched between the paper and the adhesive. It’s often – deceivingly – referred to as a “gummed” paper tape.

How is it used? When the adhesive is moistened, it creates a strong bond with porous surfaces. So, it’s sought after as tape to protect the contents of a box well, prevent tampering, and withstand harsh weather.

Is it environmentally friendly? Surprisingly not, that’s the downside. While yes it has paper in its makeup, it’s really paper-backed tape with an adhesive front. So it’s the least environmentally friendly of all of the options, because of the synthetic fibers, like fiberglass that is a signature of its makeup. When reinforced WAT is put through a machine for the application, it ends up being very expensive and more labor-intensive, because of the pesky synthetic fibers. That extra maintenance required to keep the machine working, and the lack of automation that causes waste in the process, contribute to it being a less sustainable option.

Look for further innovations in BestPack’s carton sealing products soon, as we look to diversify and offer the most environmentally friendly options available for all of our customers.