Many industries strive to enhance both efficiency and reliability in their packaging processes. This is where BestPack case sealers shine. These indispensable tools in modern packaging lines boost productivity and ensure your products are securely sealed and protected during transit. With various models tailored to different scales and technological needs, there’s a case sealer for every type of business. Dive into our detailed guide to explore the various types of case sealers and discover how to choose the right one to streamline your operations and meet your specific business needs.

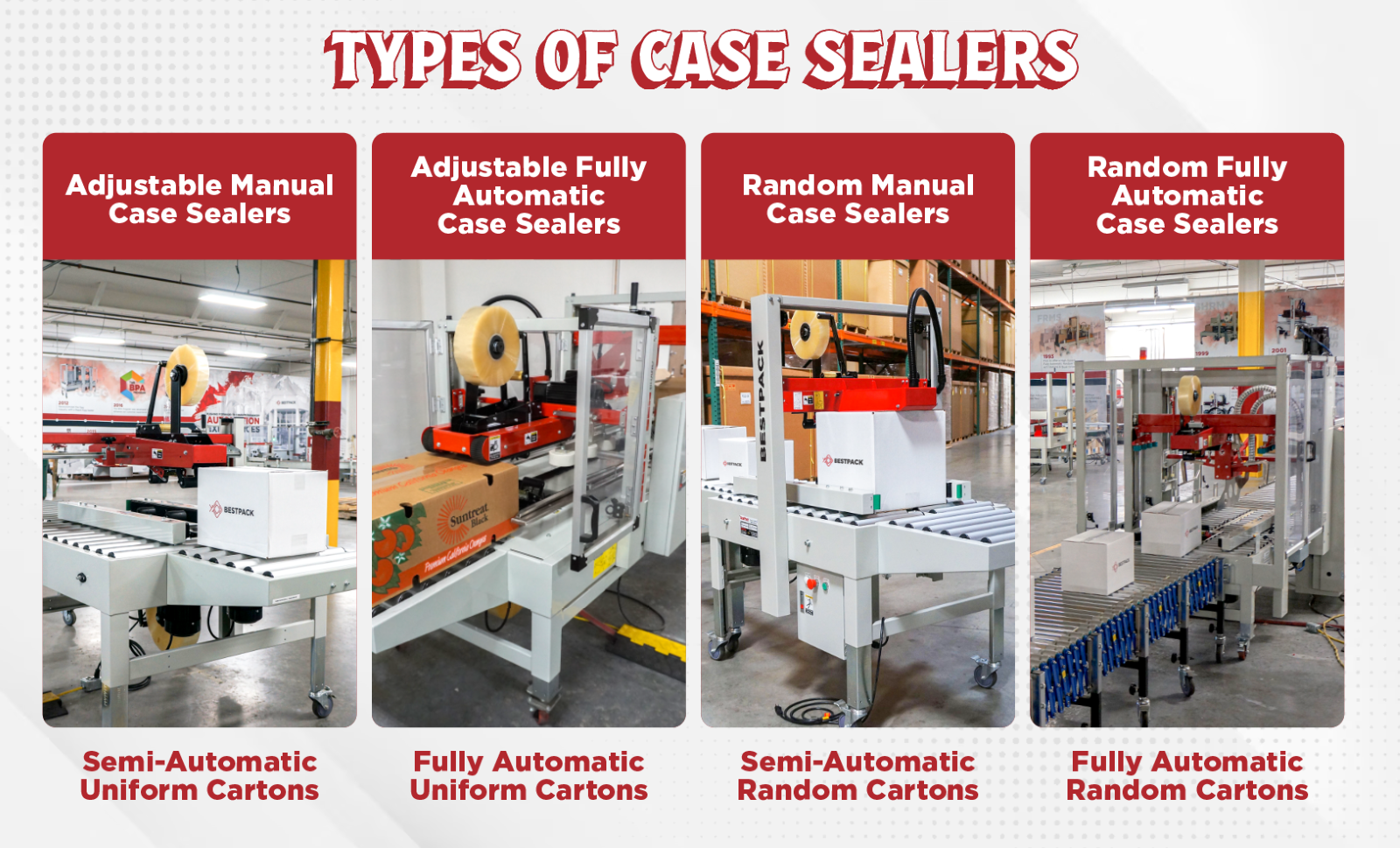

These machines suit your businesses that use uniform cartons during a shift. The operator must manually adjust the sealer for each box size. With most adjustable manual case sealers, the operator must fold the top flaps and feed the box into the machine to seal the box properly. However, they offer flexibility for smaller operations that do not require continuous sealing of different-sized boxes.

Offering a higher level of automation, these machines automatically flap fold and seal uniform boxes without manual intervention, significantly speeding up the packaging process. They are ideal for high-volume environments where sealed boxes are the same size. Due to minimal operator involvement, they help reduce labor costs and increase efficiency.

These sealers adjust automatically to different box sizes but require an operator to feed and fold the top flaps of boxes manually. They are particularly effective when box sizes change frequently at lower volumes. The manual involvement is required to space out each carton so the machine doesn’t get jammed during the carton sealing process.

These sealers are designed for a hands-off operation and can adjust to any box size fed into the solutions on the fly. They are perfect for fully automating operations that need to space out, flap fold, and seal a high volume of boxes without slowing down the production line. This type of carton sealer maximizes throughput and efficiency in diverse packing environments.

Carton sealers are invaluable assets in your production line. They automate the sealing process, enhance efficiency, reduce packaging waste, and minimize labor costs. To select the perfect carton sealer for your business, carefully weigh several key factors. This guide is here to assist you in making a well-informed decision that aligns with your operational requirements and goals. LeLet’sxplore how you can find the right fit for your needs.

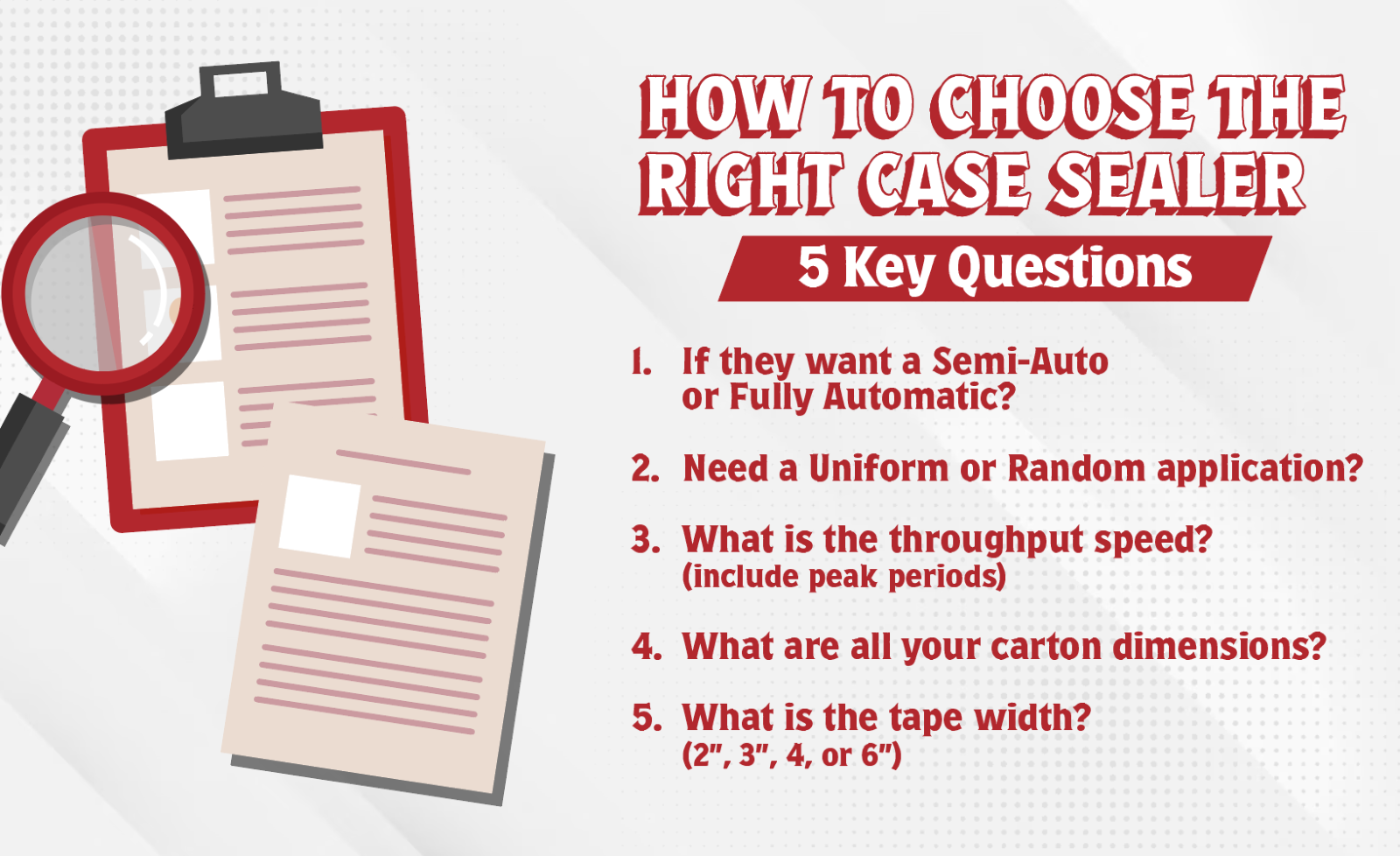

BestPack asks five critical questions to customers to get them the proper case sealer – it involves asking:

Evaluate the sizes of cartons your business typically uses. Some sealers are designed for uniform carton sizes, while others can adjust to various dimensions. If your operation requires packaging different-sized cartons, consider a machine with easy adjustability or one that automatically adapts to different sizes.

Speed is a critical factor in choosing a carton sealer. Assess the average throughput required in your packaging line to determine this speed. Higher speeds typically require more advanced and expensive machinery. Ensure the sealer can handle your operation’s peak capacity without causing bottlenecks.

Carton sealers for uniform applications typically use standard sealing materials like PVC tape, acrylic, or hot melt adhesive. For random applications,it’ss crucial to consider the strength and durability required for your packaging when choosing the sealing material. For instance, heavier shipments or those requiring long-distance transportation may benefit from more substantial, more durable seals, regardless of the application type.

The build quality of a carton sealer affects its longevity and reliability. Whether you need a sealer for uniform or random applications, choose machines made from high-quality materials known for their durability. Additionally, consider the ease of maintenance and the availability of spare parts. A machine that is easy to maintain and repair will reduce downtime and extend its service life, which is particularly important in high-variation, random applications.

Choosing Case Sealers

Choosing Case Sealers

Selecting the perfect carton sealer is essential for enhancing your packaging line and ensuring your products are securely sealed and prepared for distribution. It’s critical to consider various factors such as the different types of sealers available, the size and variability of your cartons, the speed requirements, the kind of seal, the durability of the machine, system compatibility, and your budget. By carefully evaluating these aspects, you can choose a sealer that not only boosts your operational efficiency but also supports the growth of your business. BestPack also has a fantastic tool to assist you in finding the right solution just for you. Check out our “Find Sealer” tool! This tool will help guide you to the right solution. For more info don’t, don’t hesitate to consult with BestPack to find a solution specifically tailored to meet your unique needs.

Choosing the ideal case sealer is not only about meeting the immediate needs of your operation but also about planning for future demands. Each case sealer model presents unique advantages and is designed to accommodate various operational scales and complexities. By thoroughly understanding the specifics of each model and aligning them with your operational requirements, you can significantly enhance your pack line’s efficiency and reliability. Whether you’re running a small business or a large corporation, there’s a perfect case sealer to meet your needs, ensuring your products are securely packaged and ready for shipment.

Notifications