The engineered Quality of BestPack’s carton sealers will assure

that you benefit from years of Innovation and Customization expertise.

Here are 10 reasons that will help you become more efficient, operate

more safely, cut costs, and maximize your profitability.

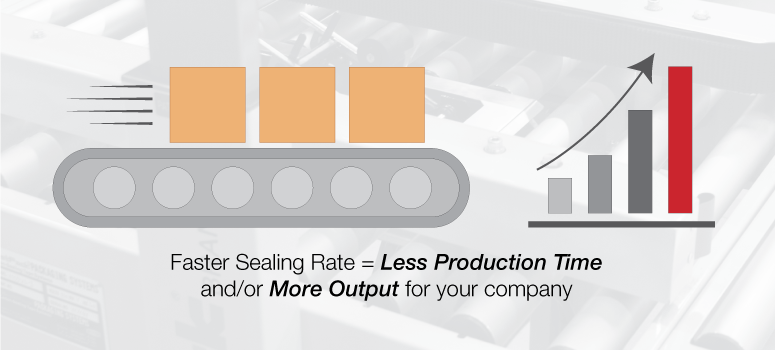

BestPack’s line of High-Speed Carton Sealers can increase your sealing rate up to 1.5 times.

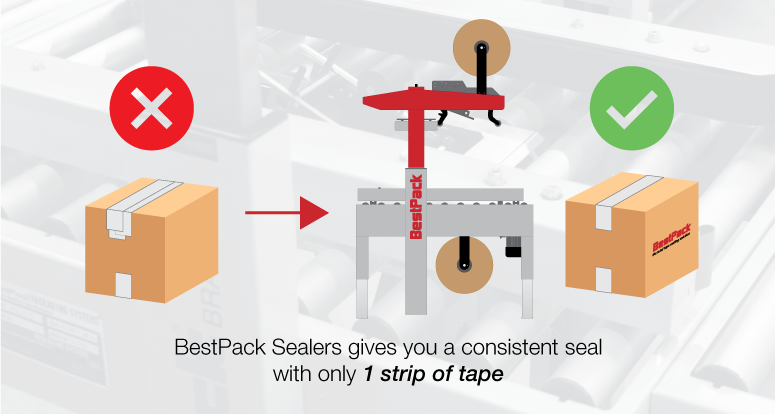

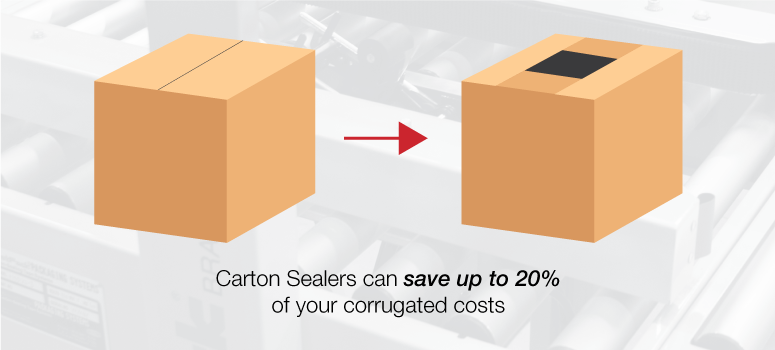

Carton Sealers only apply one strip of tape on the top & bottom of the box eliminating the

extra cost of tape when manual laborers place 3 or 4 strips of tape per box.

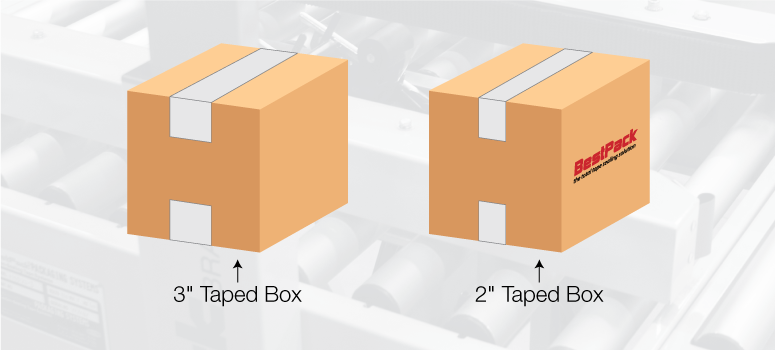

Going from 3″ tape to 2″ tape with quality tape and automation could be a possibility.

Without unnecessary strips of tape on the box, the outside packaging looks more clean-cut

and presentable for on-the-shelf presentation.

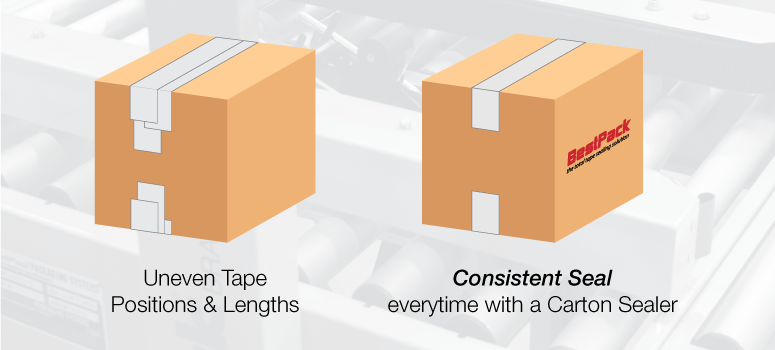

Automated carton sealers provide better and more consistent carton security for transport of

items, thus eliminating losses from pilferage.

Using staples, glue, or strapping can sometimes damage product while being packaged.

There are high maintenance costs using staple & glue sealing machines.

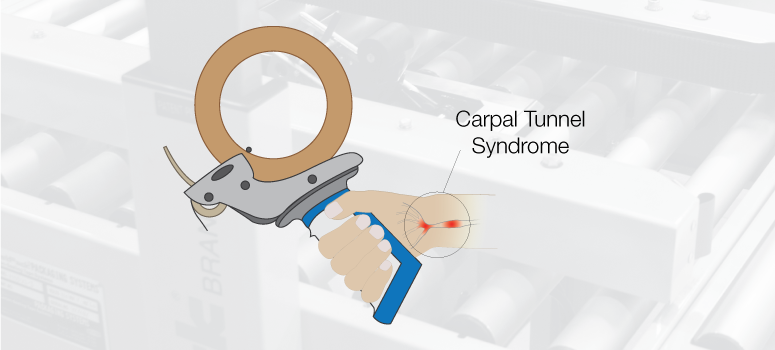

Carton Sealers will stop repetitive motion for your employees, and eliminate fatigue,

downtime, and claims for carpal tunnel syndrome.

With reduced claims and this preventive measure, workman’s comp premiums may be able to be reduced.

Carton Sealers will regulate the length of each tape tab to eliminate excessive tape costs per box.

BestPack’s R&D in carton sealing technologies has developed new solutions that can

save your company up to 20% of your corrugated & packaging costs.

|

|