Here at BestPack we pride ourselves on providing the best of the best when it comes to innovation in the packaging automation industry. Providing solutions to all industries that can benefit from the automation of their packaging lines – and the agriculture industry is no exception. Innovating to seal potato boxes, seal onion boxes, seal wine boxes, etc., all have their own specific requirements as far as boxes and sealing are concerned – and we have customized solutions specifically to meet these demands.

When your agriculture business automates it’s packaging line it has a rippling effect across multiple areas of your operation.

When your agriculture business automates it’s packaging line it has a rippling effect across multiple areas of your operation.

First and foremost, automation of your packaging line can help you to guarantee certain levels of production and efficiency. When you are capable of sealing 38 boxes per minute without an operator sealing 5 or 10 boxes per minute by hand-sealing, there is a significant difference in speed. Plus your machine can keep on going.

Additionally you can reduce production costs and the time associated with your packaging line. This is done by having your packaging process automated, which frees up your most valuable asset, the employees, to fill in other roles that can’t be automated. This helps save costs in training new hires, adding more workers to the payroll and can greatly reduce injuries associated with repetitive labor, such as erecting and sealing cartons.

Another major factor in switching over to a fully automated packaging line is the benefit of moving to 100% recycled corrugated packaging. Nowadays, companies have more and more pressure from consumers than ever before to be environmentally friendly and reduce their carbon-footprint. But this can be tough in packaging. With the use of our machines and our custom tape designed for 100% recycled corrugated cartons, this is easy to do.

Now let’s get into some specifics of how we can automate your packaging line and bring about these results:

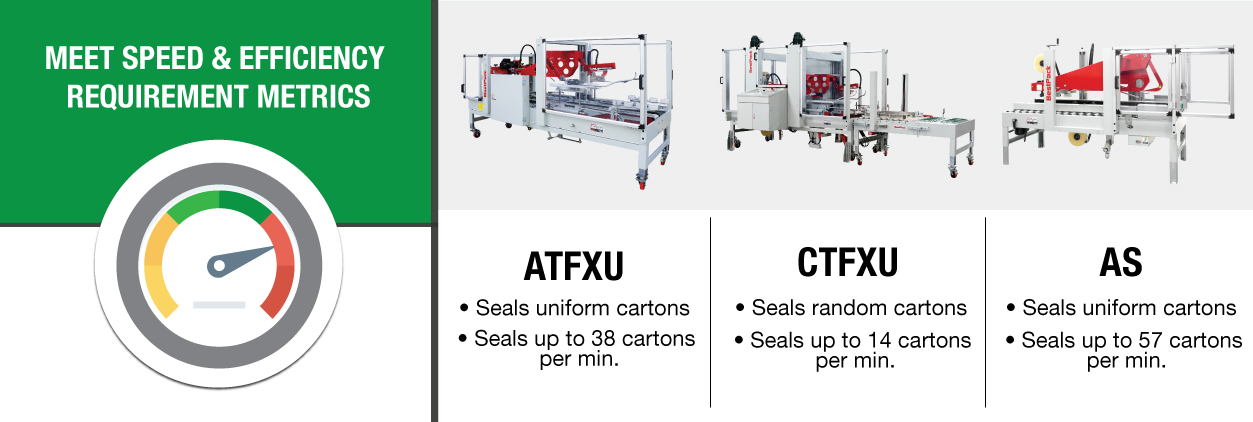

We have designed machines to specifically meet the needs of the agriculture industry. This industry has very specific needs and requirements when it comes to the types of cartons that are used to seal produce, thus there needs to be specially created machines to seal these cartons properly without loss of efficiency or quality.

The BestPack ATFXU is a prime example of this. This machine is specifically designed to seal all types of produce from, oranges, potatoes, onions, etc., making it an excellent potato box sealer, onion box sealer, wine box sealer and more. Additionally, it is able to do so at a speed of 38 cartons per minute without the need of an operator. This can greatly improve your efficiency and reduce costs in your packaging line.

Also, the BestPack CTFXU is very similar to the above mentioned ATFXU except that this machine is designed to handle random carton sizes and can seal up to 14 cartons per minute. This is ideal for those companies that have varying products that need packaging and sealing in different sized cartons.

Additionally, the BestPack AS is an operator free carton sealer designed to seal uniform cartons. With speeds of up to 57 cartons per minute it is designed to close all four top flaps and seals the top and bottom of the carton. This is a huge player in the agriculture game for a large volume of uniform cartons that need to be flap folded and sealed.

These are just some examples of how switching to an automated packaging line can help you to meet speed & efficiency requirement metrics for your business.

Switching to an automated packaging line has many benefits for your bottom line. Not only are our machines low maintenance and a better alternative than glue applications, but they also can save your business in ongoing costs significantly.

Installing an automated packaging line means that you can pivot your most valuable assets, your employees, to other tasks that can’t necessarily be automated but also likely have a lower chance of bringing about injury through repetitive motions – which is a win-win for the employees and for your ongoing expenses in payroll and potentially workers comp premiums.

Additionally, our machines seal up to at least 30 cartons per minute, which is a lot faster than can usually be done by hand-sealing cartons. Also, they don’t need to take breaks or slow down over time. They just keep sealing and sealing, which helps you meet your time requirements.

All in all, you are talking about a switch which could save you massively in production costs and time in the long-run.

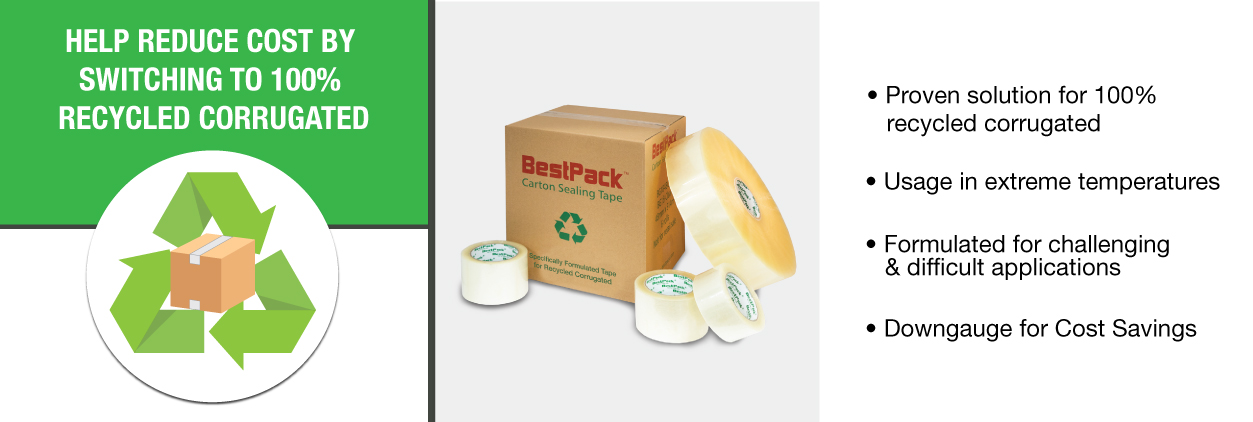

Nowadays companies have more pressure than ever before to lower their carbon-footprint and switch to more environmentally friendly products, materials and solutions by consumers. Here at BestPack we fully support this movement and have specifically designed solutions to help companies to make that switch in their packaging lines.

When considering switching to 100% recycled corrugated, companies often have to weigh the effectiveness of these cartons to their existing line and one issue which arises is how to seal these boxes properly. To solve this problem, BestPack specially designed the BG Tape as a specially formulated adhesive to properly seal 100% recycled corrugated and is so effective it can be used for produce or food as well. This helps make 100% recycled corrugated a truly cost-efficient packaging option and makes it so switching can be painless and easy.

The BestPack BG Carton Sealing Tape is sold exclusively at BestPack only. No other manufacturer has this product. If you don’t think that shipping packages affects your business, think again. Impress your customer base with enhanced packaging, while reducing costs and increasing output. BestPack automation and innovation has you covered for all your packaging needs. Contact us today!