In the bustling domain of dental service providers, where precision and timeliness dictate success, managing a seamless operational flow from product creation to delivery becomes pivotal. Arklign, a beacon of innovative solutions in the dental lab experience, found itself grappling with logistical bottlenecks that challenged its commitment to providing prompt, error-free services. With an operation that melds high-quality full-service laboratory offerings with its Arklign Case Relationship Management (aCRM) online platform, ensuring a reliable, consistent, and efficient packaging process became imperative to upholding its ethos.

Arklign, a powerhouse in revolutionizing the dental lab experience, has been driving transformative change with a holistic and integrative methodology.

Their rapid ascension in the dental service landscape has firmly positioned them as a crucial influencer, delivering comprehensive solutions that fluidly connect and optimize the myriad aspects of dental service provision. Their trailblazing initiatives and dedication to achieving excellence have positioned them at the vanguard of confronting and dismantling the inefficiencies plaguing the dental industry. They have cultivated enhanced communication channels and nurtured strong relationships across the entire spectrum of stakeholders.

Nevertheless, their impressive growth trajectory brought with it complex logistical and packaging challenges, posing potential hindrances to their momentum. The escalating need for additional manpower, the premium on space, and the imperative for absolute accuracy and consistency in packaging emerged as critical issues. Arklign’s ambitious goal to elevate their throughput to an impressive 300+ shipments per day highlighted the need for swift and effective solutions.

Examining these challenges more closely, it becomes evident that Arklign faced significant hurdles in maintaining consistency in their packaging processes.

The inconsistent taping not only detracted from operational efficiency but also risked tarnishing the company’s image in the eyes of their valued clientele. The pressure to meet FedEx’s strict pickup timelines further intensified these challenges, leading to increased instances of mislabeling and a consequent decline in customer satisfaction. Confronted with these realities, Arklign recognized that transitioning towards packaging automation was not merely a strategic decision but an essential move to secure their future success.

In BestPack, Arklign found a partner that mirrored their commitment to innovation, quality, and excellence. The solutions provided by BestPack promised to not only alleviate Arklign’s immediate packaging challenges but also to propel them even further in establishing their dominance and innovative prowess in the dental service sector. This partnership between Arklign and BestPack serves as a shining example of what is possible when two forward-thinking companies come together, committed to pioneering solutions that uplift industry standards and pave the way for future advancements.

Delving into the crux of the challenges faced by Arklign, “We started to see delays in getting our shipments prepared before FedEx pickup time daily. Due to rushing, we experienced mislabeling of shipments and experienced upset customers. We also saw our taping looked inconsistent and messy which gave a negative impression to our customers,” described Arklign’s Executive.

Clearly, a solution that addressed manpower, space constraints, and maintained consistency in their packaging and throughput of 300+ shipments per hour was sorely needed.

When exploring possibilities for improvement, Arklign, despite its lean towards technical and digital solutions, sought machinery that echoed reliability, ease of use, and minimalistic maintenance.

“The build quality and simplicity for the price point you pay,” struck a chord with the team at Arklign as they sought to embrace automation without an intricate technical overhaul, seeing that “BestPack machines were designed and built like Toyotas.”

In the quest for solutions that embodied their values of adaptability, modularity, and scalability, Arklign found their match in BestPack’s offerings.

“The search for a packaging solution required a meticulous evaluation of the options available in the market. What became evident was the prevalence of solutions that were not only costly but also laden with complexity, making them unsuitable for our dynamic and agile operational ethos.

Our company is engineered to swiftly adapt to the evolving demands of our customers, necessitating tools that are modular and scalable, capable of growing with us and adapting as necessary,” the Executive insightfully shared.

In this context, the BestPack RS22 Sealer, paired seamlessly with the BestPack Print & Apply Solution, stood out as the optimum choice. This combination offered a solution that was not just scalable and cost-effective, but also straightforward in its operation, aligning perfectly with Arklign’s organizational culture and operational requirements.

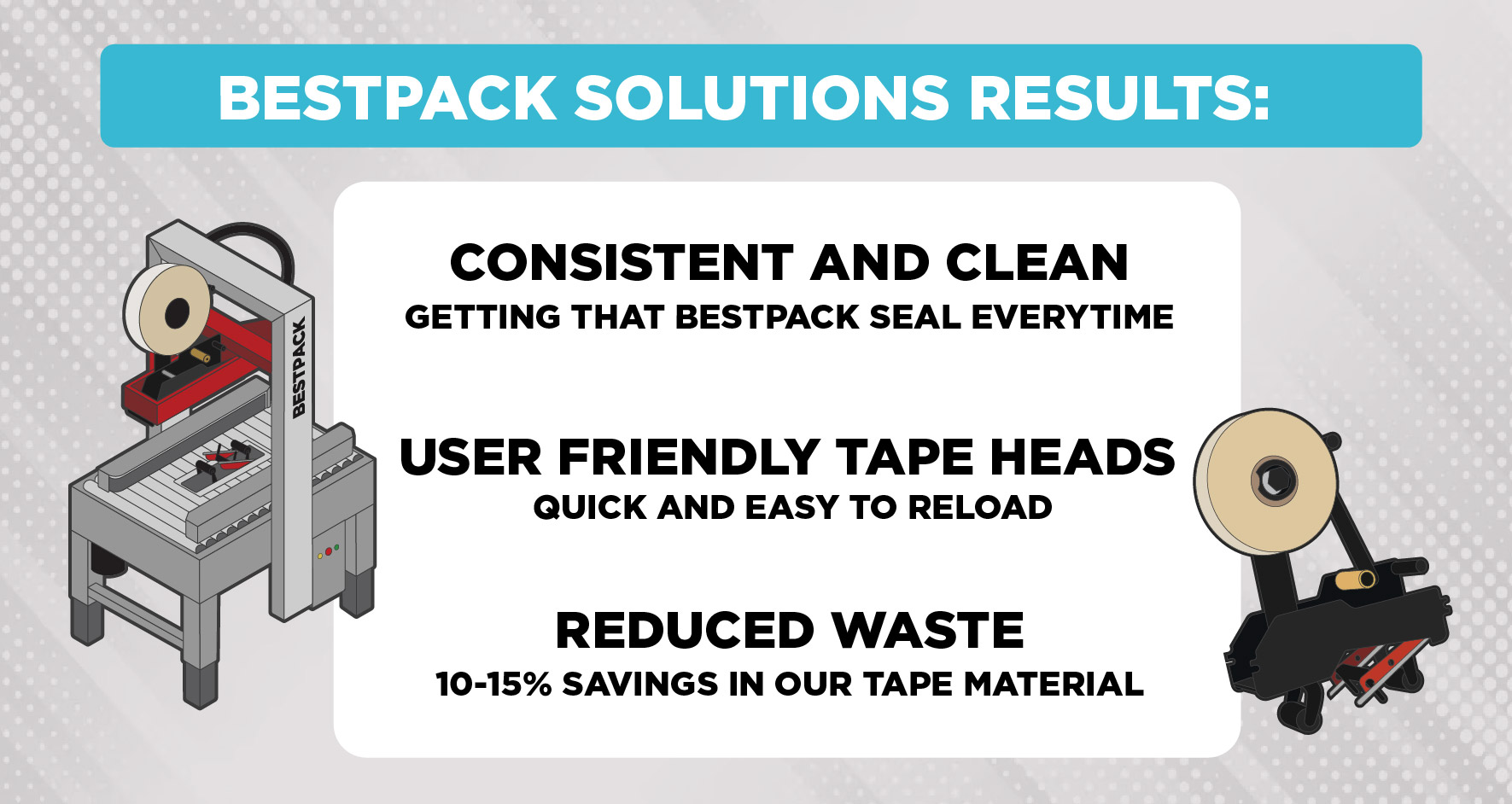

Since the integration of BestPack’s solutions, Arklign witnessed a transformation in its packaging quality, achieving “consistent and clean” results, while also observing a noteworthy “10-15% savings in our tape material” thanks to reduced waste.

The simplicity in operations was also echoed in their experience with BestPack’s Tape Heads: “Whenever we need to install new tape, it’s an easy swap and we are good to go in minutes,” ensuring that versatility and efficiency were never compromised.

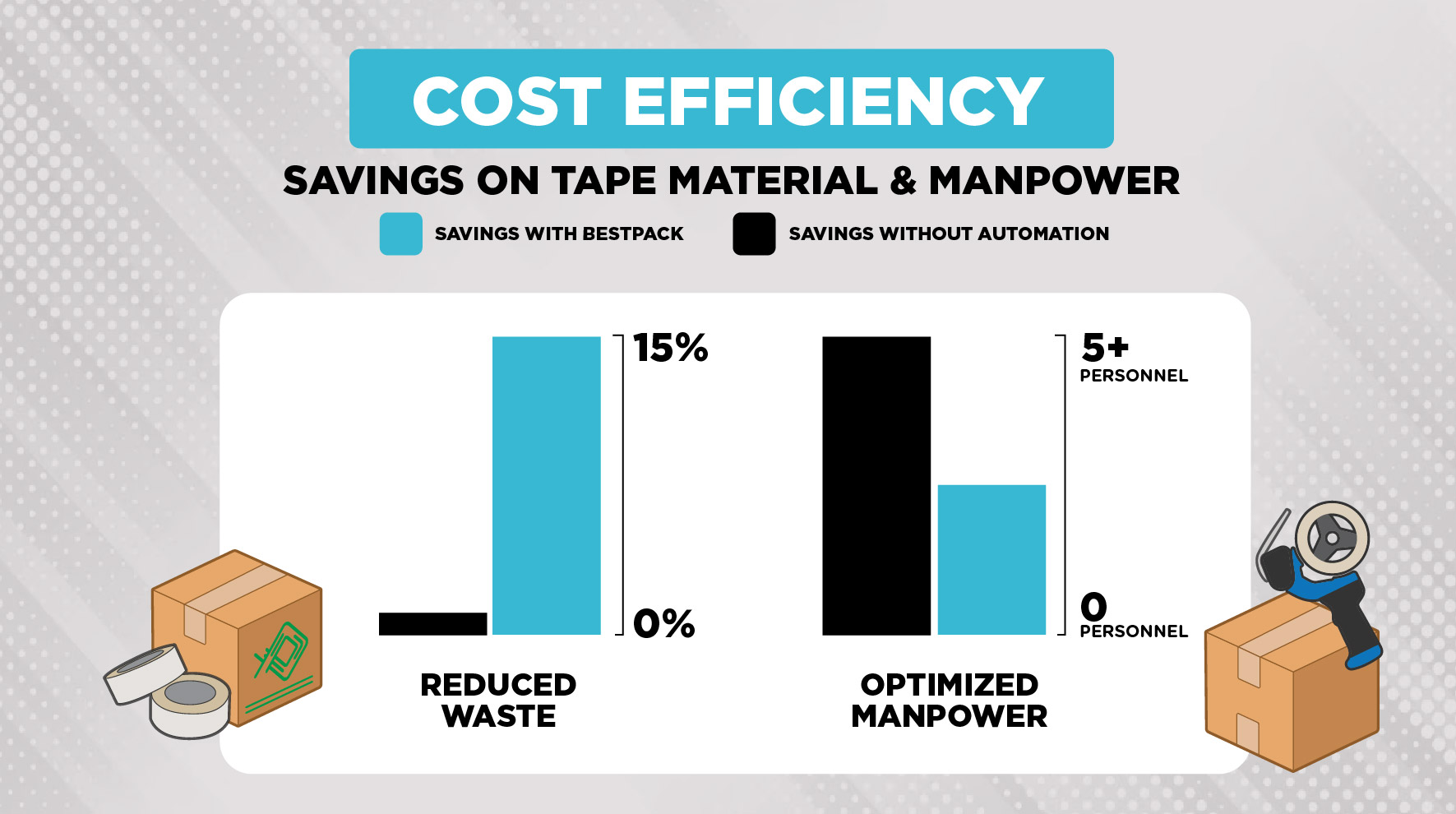

On the topic of return on investment, the Arklign representative highlighted a potent impact, stating that “For the volume we shipped at 300+ shipments per day, we required 4-5 personnel to tape to meet pickup time. Now we are down to 2 and in some cases, one person can run the tape machine and stock the shipments on lower volume days.”

This 50% reduction in manpower and cost delivered tangible proof of the impactful ROI BestPack brought to their operations.

Perhaps one of the most pivotal aspects of Arklign’s journey with BestPack was the emergence of a relationship founded on trust and a genuine commitment to delivering apt solutions.

“What I like working with BestPack, is they are not trying to push any product to me but really trying to find a solution that best fits my company’s needs. Even when I was interested in one of their more expensive solutions, they recommended I first try the entry-level machine since it already fit my requirements. This is a company I can trust,” affirmed Ray Alde, Arklign’s Executive.

This rich, layered experience of transformative change, empowered by BestPack’s commitment to delivering not just a product, but a solution, creates a narrative that speaks volumes about the brand’s dedication to customer success, sustainability, and innovation.

Peering into the horizon, Arklign’s experience with BestPack not only underscores a solution to a present predicament but also navigates the pathways towards a future enriched with scalable, flexible, and sustainable operational frameworks.

The integration of BestPack’s RS22 Sealer and Print and Apply Solution was not a mere stop-gap measure but an investment in a system that affirms Arklign’s operational adaptability and commitment to uncompromising service quality.

In the ever-evolving landscape of dental lab services, where adaptability and scalability are paramount, the modularity of BestPack’s solutions emerges as a fulcrum of future expansion plans for Arklign.

The latter emphasizes a culture that “quickly changes to the demands of our customers” and therefore necessitates a packaging solution that not only meets current demands but also “easily scales as we grow or reconfigures as needed,” as explained by Ray Alde, Arklign Executive.

Moreover, sustainability holds pivotal importance for a progressive brand like Arklign.

With the integration of BestPack’s efficient tape machines, Arklign not only minimized the manpower needed per operation but also significantly curtailed its material wastage, witnessing “10-15% savings in our tape material.”

The conspicuous impact on reducing resource consumption aligns seamlessly with sustainability objectives, providing a blueprint for future operational strategies to navigate the careful balance between efficacy, cost-management, and environmental responsibility.

The dental services sphere is perpetually dynamic, where evolving customer expectations and the integration of novel technologies incessantly reshape operational requisites.

Arklign, with its hands firmly gripped on the pulse of tech-driven solutions, would likely explore avenues where BestPack’s offerings can be further integrated into upcoming operational expansions or new logistical challenges.

An intriguing exploration would be discerning how BestPack’s machinery could dovetail with potential expansions in Arklign’s product lines, customer bases, or even geographical service areas.