Every business knows that packaging matters. It has to protect your product, showcase your branding, and catch the eye of consumers on a crowded shelf. But with so many packaging options, how do you decide what’s right for your business?

Flexible film offers a combination of protection, flexibility, and cost-effectiveness that makes it the perfect choice for a wide range of products.

Flexible film packaging encompasses a whole range of materials, from plastic films and foils to laminates. It’s exactly what it sounds like – flexible material that wraps and conforms to the shape of your product.

We understand that choosing the right flexible film packaging equipment is essential for achieving the perfect combination of product protection, aesthetic appeal, and streamlined operations.

Our other company, BPX Solutions, provides you with an exceptional range of flexible film-wrapping solutions.

We offer a comprehensive range of machinery to help you achieve the perfect packaging outcomes, including:

Here’s a more detailed look into our flexible film-wrapping equipment:

L-bar sealers are versatile machines that form the backbone of many shrink-wrapping operations. They work by creating a two-sided sealed pouch around your product.

This pouch is sent through a shrink tunnel, where heat causes the film to shrink tightly around the product, providing a classic, professional-looking package. It is ideal for a wide range of products that need secure, tamper-evident wrapping.

BPX Solutions offers L-bar sealers to meet a wide range of production needs:

Need to package products of varying sizes, including extra-long items? Side sealers offer incredible flexibility. They create a continuous tube of film that completely encloses your product, sealing along the side and then separating packages downstream.

This makes them perfect for everything from single items to long, irregularly shaped products that wouldn’t fit on a traditional L-bar sealer.

BPX solutions offers both medium- and high-speed choices:

After your product is sealed in shrink film, the shrink tunnel is where the magic happens!

These specialized tunnels apply controlled heat to the film, causing it to shrink and conform tightly to the product’s shape. The result is a securely wrapped, visually appealing package that’s ready for display or shipping.

BPX Solutions provides the right tunnel to complement your sealing process, whether you’re working with a combo system or need a standalone solution:

If you need to individually package products, especially small, delicate, or oddly shaped ones, flow wrappers streamline the process.

They envelop each item in a custom-sized film pouch, then seal it on three sides. This provides excellent product protection and a neat presentation that’s perfect for retail environments or for grouping items together for sale.

BPX Solutions offers options for both speed and handling:

Bundle multiple products together quickly and efficiently with poly bundlers. These machines use film to create a “sleeve” around a group of items, securing them together for streamlined handling and storage.

They’re a great way to create multi-packs, promotional sets, or simply to bundle products for easier distribution. Poly bundlers are especially useful for packing up bottled products and drinks, streamlining operations in the beverage industry.

Here’s what we have:

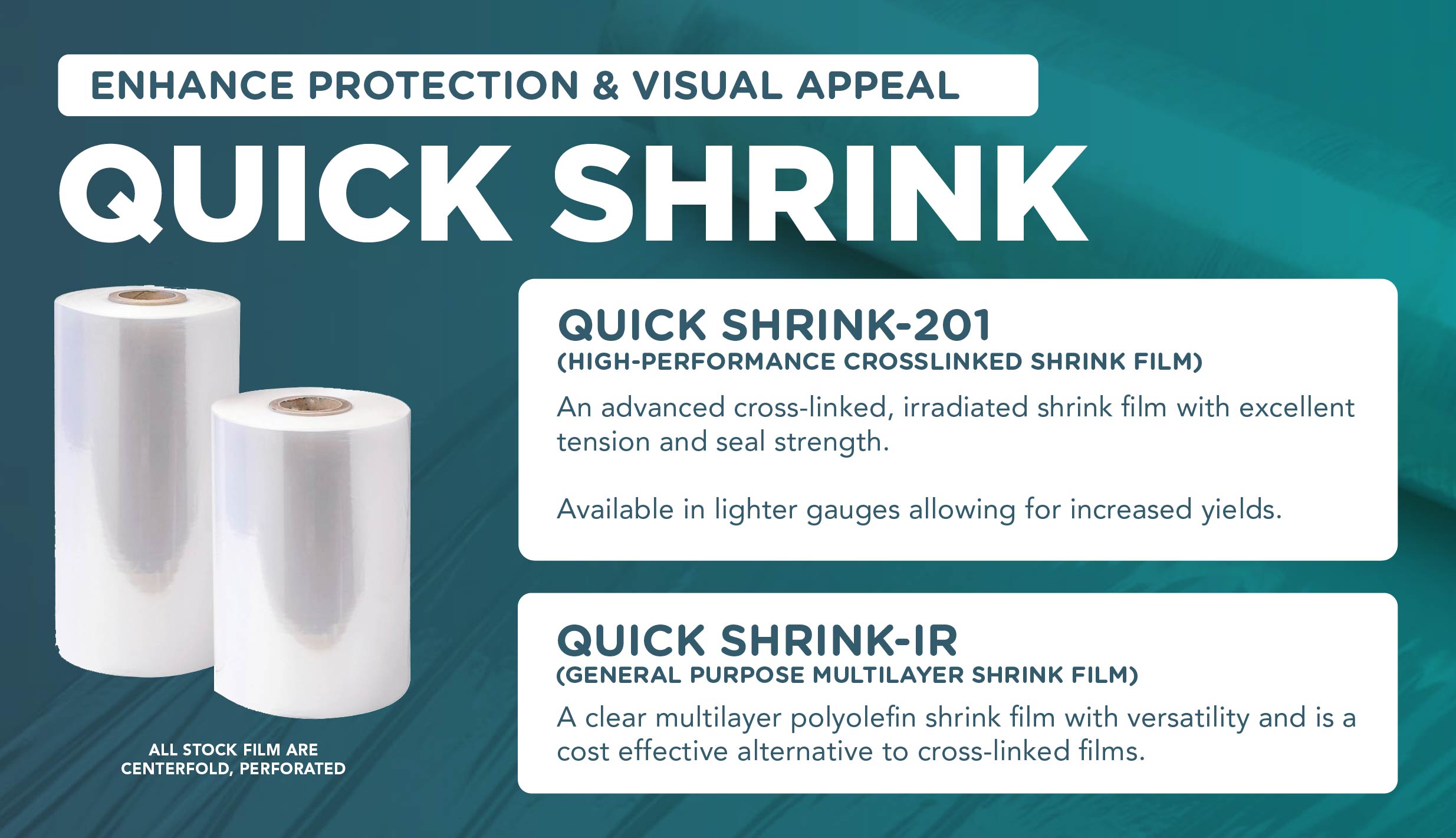

BestPack Shrink Wrap Products: Enhance Protection and Visual Appeal

BestPack, with over 30 years in the packaging industry, understands the importance of high-quality shrink-wrap film.

Partnering with leading film manufacturers, we offer exceptional shrink wrap products, FDA and USDA-approved, to elevate your packaging and protect your products effectively:

Here’s what we offer in this area:

This is a more budget-friendly option that still provides excellent clarity and a nice shine. It’s strong enough for most jobs and works well with many different shrink-wrap machines. Think of it as the reliable workhorse that gets the job done at a good price.

Think of this as the heavy-duty option. It’s super clear, like a high-definition window, so your product looks fantastic. While thinner than some other shrink film options, Quick Shrink-IR offers exceptional strength and tear-resistance due to its specialized crosslinking process. This makes it ideal for delicate items or those with sharp edges. Plus, it works well with a wide range of shrink-wrap machines, so it’s a versatile choice.

| Feature | Quick Shrink-IR | Quick Shrink-201 |

| Clarity | Excellent (Crystal-clear) | Very Good (High Gloss) |

| Strength | Superior (Puncture resistant) | Good (Strong for most jobs) |

| Sealing Temperature Range | Wide | Good Range |

| Cost | Higher | More Budget-Friendly |

| Best For | High-demand applications, delicate items, odd shapes | Most general packaging needs |

Recent tax legislation offers a compelling opportunity to upgrade your packaging processes while reaping significant tax benefits.

Businesses can now deduct 100% of the cost of new machinery and equipment investments immediately. This translates to substantial tax savings and makes investing in automation even more attractive.

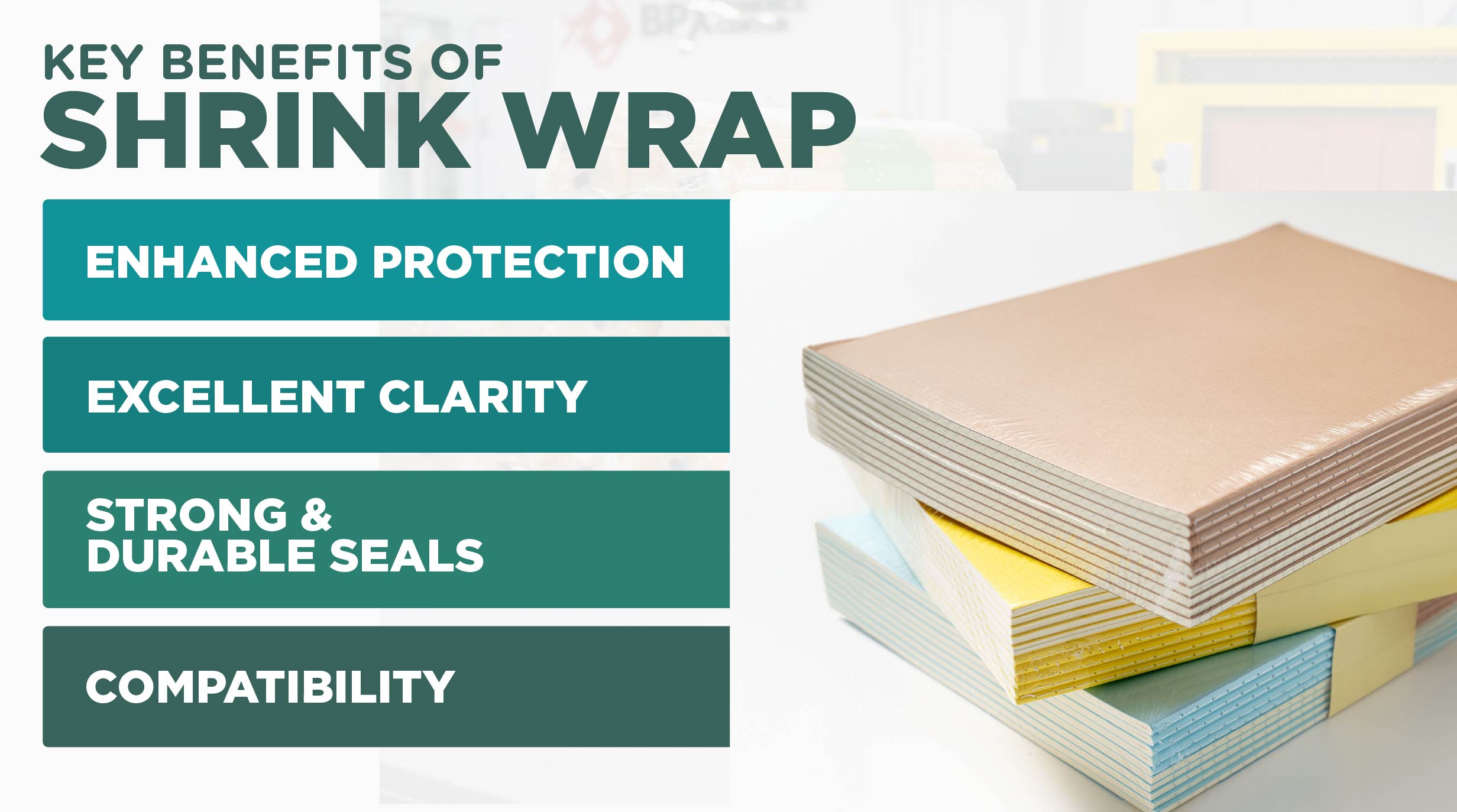

Flexible film packaging provides a powerful blend of protection, visual appeal, and cost-effectiveness for your products. By choosing the right equipment and film solutions, you can streamline your operations and boost your bottom line.

BestPack and BPX Solutions are your partners in achieving packaging excellence. We offer industry-leading shrink wrap film, a wide array of flexible film equipment, and the expertise to guide you toward the perfect fit for your needs.

Don’t miss out on the chance to optimize your packaging and maximize your savings with the valuable tax incentives we mentioned.

Contact BestPack today for a free consultation and let us help you elevate your packaging operations!