In the food packaging industry, efficiency and quality are paramount, and BestPack is committed to delivering both with our range of advanced packaging solutions.

Our L-bar sealers are integral to this effort, designed to protect your products while enhancing productivity. Whether you’re handling fresh produce, frozen foods, or processed snacks, our L-bar sealers provide the perfect combination of precision, speed, and flexibility.

BestPack’s L-bar sealers aren’t just machines—they’re essential tools that transform your packaging processes.

As we approach the harvest season in 5-6 months, now is the perfect time to invest in the right equipment. Whether you’re focused on maintaining freshness, enhancing safety, or improving efficiency, our products are designed to meet the unique demands of your business.

The airtight seals created by our L-bar sealers are crucial for keeping fresh produce and other perishable items in peak condition.

By minimizing exposure to air and contaminants, these seals help extend the shelf life of your products. Whether you’re packaging fruits, vegetables, or herbs, shrink wrapping with an L-bar sealer keeps the freshness locked in, reducing waste and ensuring customer satisfaction.

Tamper-evident packaging has become more important than ever, and BestPack’s L-bar sealers excel at creating secure, transparent packaging that instantly shows if it has been disturbed.

This is critical for high-value items like organic produce and frozen meals, where consumer trust is paramount.

Our L-bar sealers are designed for speed and reliability, allowing you to package large quantities of goods quickly without sacrificing quality.

Whether you’re preparing for the busy harvest season or trying to keep up with increasing demand, BestPack’s machines help you stay ahead of the curve. Features like automatic product adjustment and variable speed drives ensure that you can handle different product sizes and types with ease.

Investing in an automated L-bar sealer doesn’t just boost your efficiency—it can significantly reduce your labor costs as well. With our fully automatic models, you can minimize manual involvement, freeing up your team to focus on other tasks.

Additionally, automation ensures a consistent and precise seal every time, which reduces material waste and increases overall packaging efficiency. By integrating BestPack’s L-bar sealers into your production line, you’ll experience smoother operations with lower material and labor costs.

At BestPack, we understand that no two packaging lines are alike. That’s why we offer a wide range of solutions for each of our L-bar sealer models, designed to handle everything from shorter to longer sealing requirements. Along with this, we provide a variety of shrink tunnels and other accessories to help enhance and improve your production line.

From adjusting the sealing width and speed to configuring the shrink tunnels for optimal performance, every aspect of our L-bar sealers can be customized to meet the specific needs of your packaging operation. Whether you’re sealing delicate fresh produce or large, bulky frozen items, BestPack has the flexibility and precision to handle it all.

If you need a machine that handles a wide variety of product sizes or one designed for high-speed production, BestPack has you covered.

One of the key advantages of BestPack’s L-bar sealers is their small footprint. For facilities with limited floor space, maximizing every square inch is crucial. Despite their compact size, our L-bar sealers provide the automation and efficiency businesses need to grow.

Whether you’re working in a small warehouse or a large distribution center, BestPack’s L-bar sealers offer high performance without taking up unnecessary space, making them the perfect fit for any packaging environment.

To really see how BestPack stands out, let’s dive into some of our top-performing L-bar sealers, each designed to meet a range of food packaging needs.

The PP-48ST is a unique addition to our lineup, combining an L-sealer with a hooded shrink chamber in one complete unit. This semi-automatic machine is ideal for businesses looking for compact and versatile solutions. While it handles up to 6-8 packages per minute, it offers unparalleled precision by using a vacuum chamber to shrink the product, rather than a traditional shrink tunnel.

With features like “Band Seal Technology” (which eliminates the need to replace seal wires) and an automatic pinwheel hole punch, the PP-48ST is a great fit for packaging PVC or Polyolefin shrink films. This machine is perfect for businesses that prioritize quality and compactness in their packaging processes but don’t require high-speed automation.

The PP-1519ECMC is perfect for businesses seeking an entry-level solution that doesn’t compromise on performance. Compact and highly efficient, this model is designed for low to medium production speeds, handling up to 12 packages per minute.

The PP-1519ECMC stands out as a unique, all-in-one solution for businesses looking to combine sealing and shrink-wrapping in a single, compact machine. This combination of an L-bar sealer with a shrink tunnel makes it possible to efficiently shrink-wrap products immediately after sealing, all in one seamless step.

For small food businesses or those in seasonal industries, this machine provides an ideal blend of efficiency and space-saving. By integrating both processes—sealing and shrinking—into a single unit, the PP-1519ECMC helps you reduce the time spent on packaging while ensuring your fresh produce or processed goods are securely wrapped and ready for distribution.

With Micro Knife technology for precise seals and a fully recirculating air chamber for consistent shrink-wrapping, this machine keeps your products fresh while lowering packaging costs and streamlining your workflow.

For those with higher production needs, the PP-1622MK is a heavy-duty option capable of running up to 15 packages per minute across two shifts.

Built with durability and precision, this model features the versatile Micro Knife Seal Technology for consistent sealing. Additionally, there’s a hot knife (HK) option, perfect for sealing heavier films such as polyethylene, providing a durable and consistent seal that minimizes downtime and boosts efficiency.

Whether you’re packaging frozen foods that require tamper-proof wrapping or processed goods that demand consistent presentation, this L-bar sealer ensures the reliability and speed necessary for large-scale operations.

The stainless steel film clamps and motorized discharge conveyor make it a highly efficient choice for larger businesses preparing for peak production during harvest season.

If you’re just starting to automate your packaging process, the PP-5545TBA offers an affordable yet highly effective solution. Capable of handling up to 25 packages per minute, this machine features a Teflon-coated hot knife seal blade for precise, consistent sealing every time.

Its compact size and easy-to-use design make it ideal for small to medium-sized food businesses looking for an economical way to increase output without sacrificing quality. To maximize the efficiency of your system, pairing the PP-5545TBA with one of BestPack’s shrink tunnels will complete the process, providing a seamless transition from sealing to shrink-wrapping.

The addition of a shrink tunnel enhances your production line by ensuring a tight, uniform shrink wrap, which further protects your products from contaminants, enhances presentation, and adds tamper-evidence. By completing the system with a shrink tunnel, you reduce the need for manual handling and speed up the packaging process, making your business even more efficient during peak production periods.

The fully automatic operation and self-contained scrap removal system minimize manual intervention, saving you time and labor costs, while the integration of a shrink tunnel guarantees the final product is both sealed and shrink-wrapped to perfection.

When speed and efficiency are crucial, the PP-5600CS is the ideal solution for large-scale food production. Capable of handling up to 40 packages per minute, this fully automatic L-bar sealer is perfect for businesses processing everything from fresh produce to frozen foods.

With food packaging demands continually growing, especially during peak seasons like the harvest period, the PP-5600CS can help streamline operations with its Automatic Product Adjustment (APA) feature.

This makes it incredibly easy to switch between different product sizes, whether you’re packaging small, delicate fruits or larger trays of frozen meals. The precision in sealing ensures that fresh produce remains properly wrapped, retaining freshness and extending shelf life, while frozen products are securely sealed to prevent freezer burn and contamination.

Designed for businesses looking to scale their operations with minimal labor involvement, the PP-5600CS significantly reduces manual handling while increasing productivity. Its ability to handle varied food products makes it a versatile and high-performance machine, ensuring consistent, reliable packaging.

This is especially beneficial for companies in the food industry preparing for increased output during the busy harvest season, when both speed and precision are critical to meeting market demands.

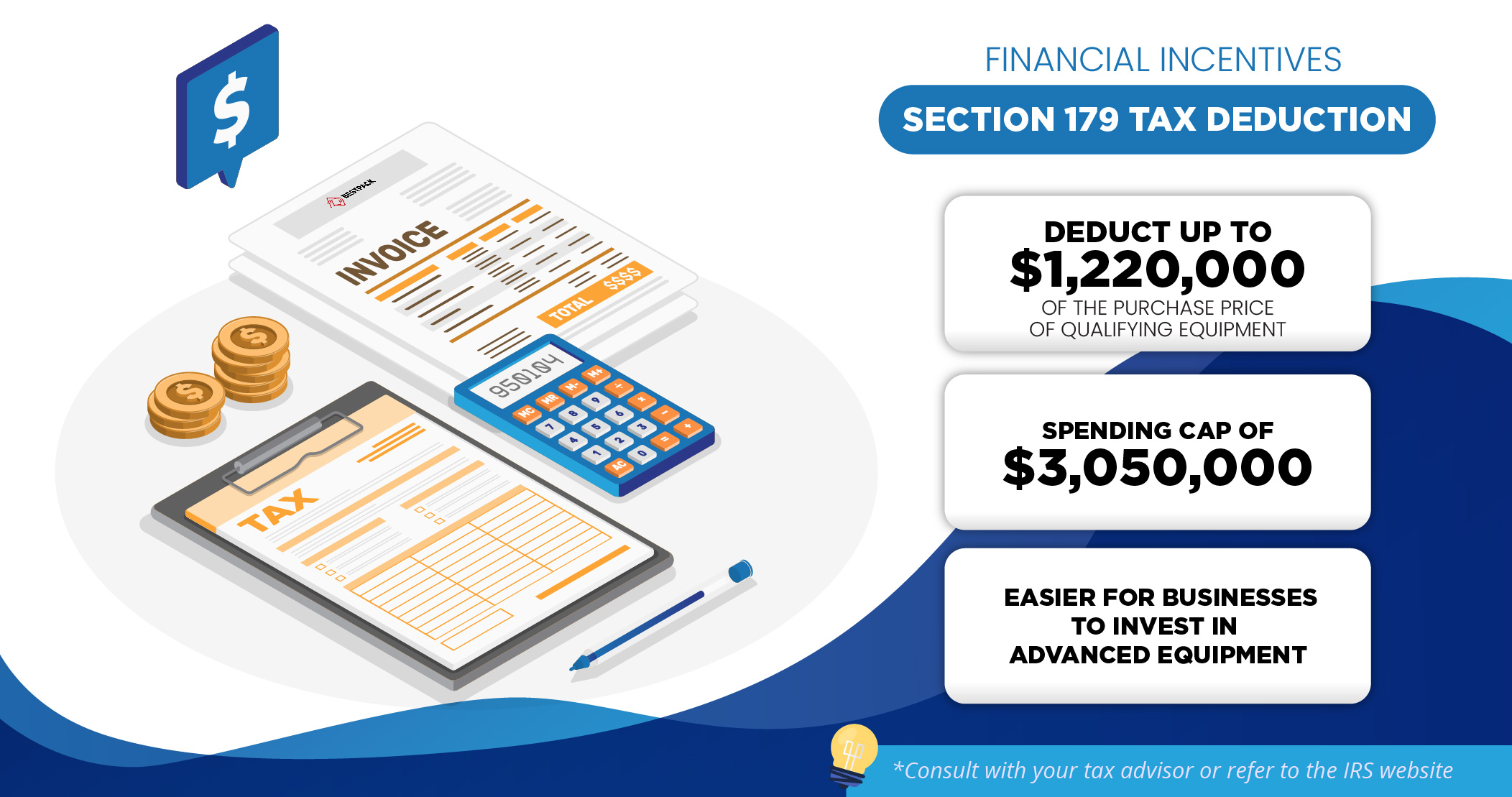

Beyond the superior technology and efficiency that BestPack’s machines bring, there are financial benefits as well—specifically through the Section 179 tax deduction.

In 2024, businesses can deduct up to $1,220,000 of the purchase price of qualifying equipment, including our L-bar sealers, with a spending cap of $3,050,000. This tax incentive significantly reduces the net cost of acquiring new packaging machines, making it easier for businesses to invest in advanced equipment before the busy harvest season kicks in.

By taking advantage of Section 179, you not only improve your production capabilities but also reduce your tax burden, creating a win-win scenario.

If you’re thinking about upgrading your equipment or automating your packaging process, now is the time to act. For more detailed information on how to leverage Section 179, be sure to check out our comprehensive guide on the subject!

Regardless of whether you’re packaging fresh produce, frozen goods, or processed snacks, BestPack’s L-bar sealers offer the precision, speed, and flexibility you need to take your business to the next level.

Our commitment to customization ensures that you’ll get a machine tailored to your specific needs, and with the financial incentives offered by Section 179, there’s no better time to invest in new equipment.

With over 35 years of experience and a presence in 48 countries, BestPack is more than just a supplier—we’re a partner in your success. Let us help you streamline your packaging process and deliver the best possible products to your customers.