How to Use a Case Erector: Step-by-Step Packaging Guide [2024]

As automation redefines the packaging industry, case erectors have become essential tools for businesses aiming to improve productivity and ensure consistent, high-quality packaging. In this article, we’ll walk you through how to use a case erector in 2024 and outline the operational procedures, safety guidelines, and troubleshooting tips to optimize efficiency and output.

What is a Case Erector?

A case erector is a machine designed to automatically shape flat cardboard into erect cases, seal the bottoms with tape, and make them ready for filling. In 2024, modern case erectors often come equipped with smart technology, allowing for monitoring, remote control, and troubleshooting, thus further streamlining packaging processes.

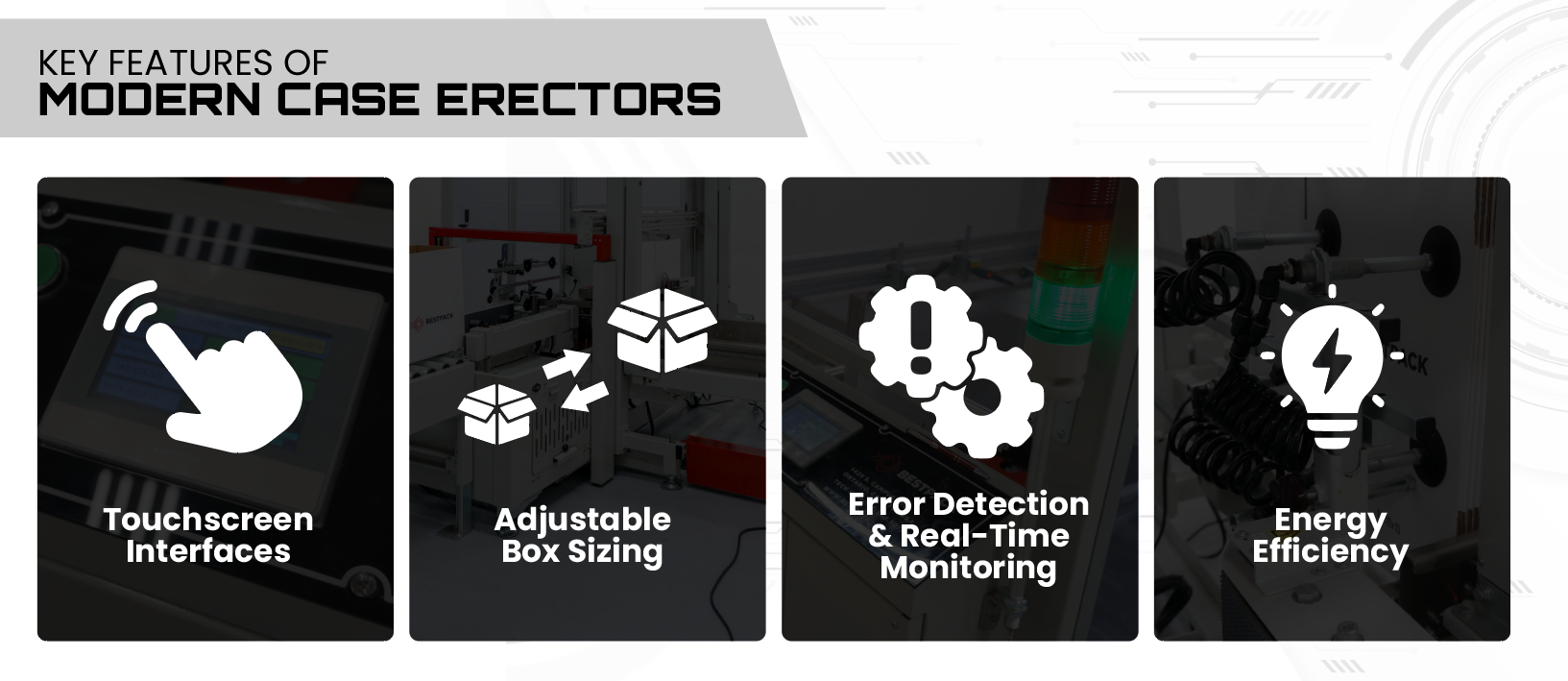

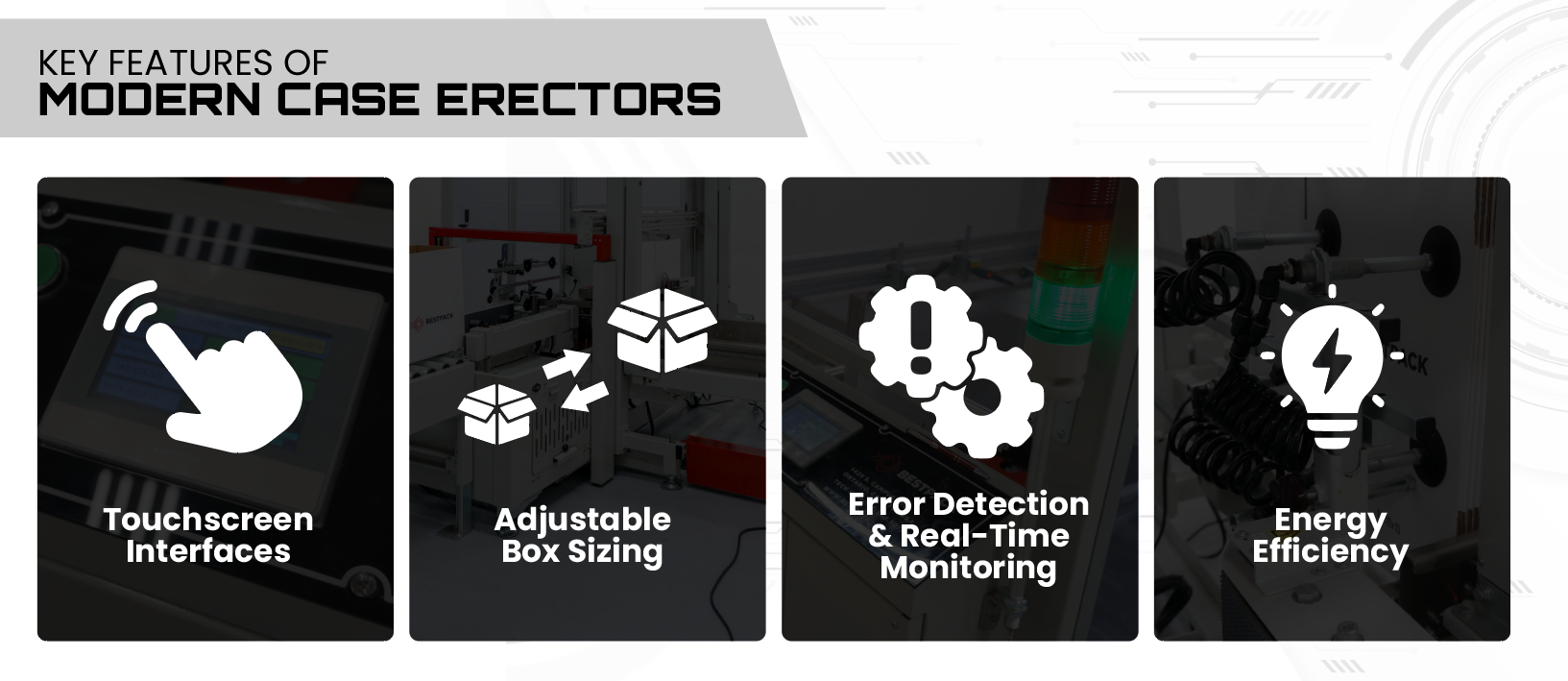

Key Features of Modern Case Erectors

Today’s case erectors offer advanced features, including:

- Touchscreen Interfaces: Equipped with an intuitive, easy-to-navigate control panel, allowing operators to view and troubleshoot issues with the case erector quickly.

- Adjustable Box Sizing: Adapts to various box sizes without manual adjustments.

- Error Detection and Real-Time Monitoring: Sensors identify issues with case positioning or sealing, while real-time alerts notify operators of any disruptions.

- Energy Efficiency: Reduces power consumption with improved components.

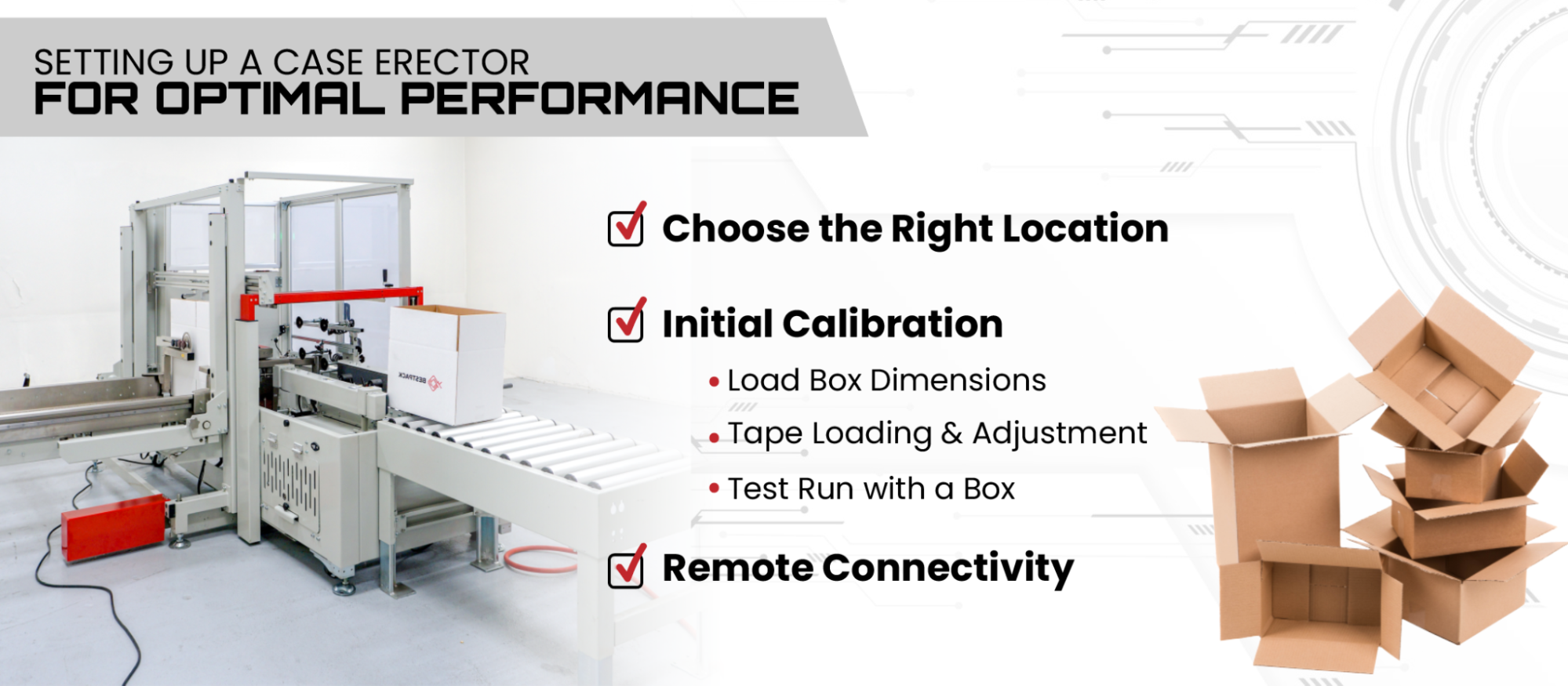

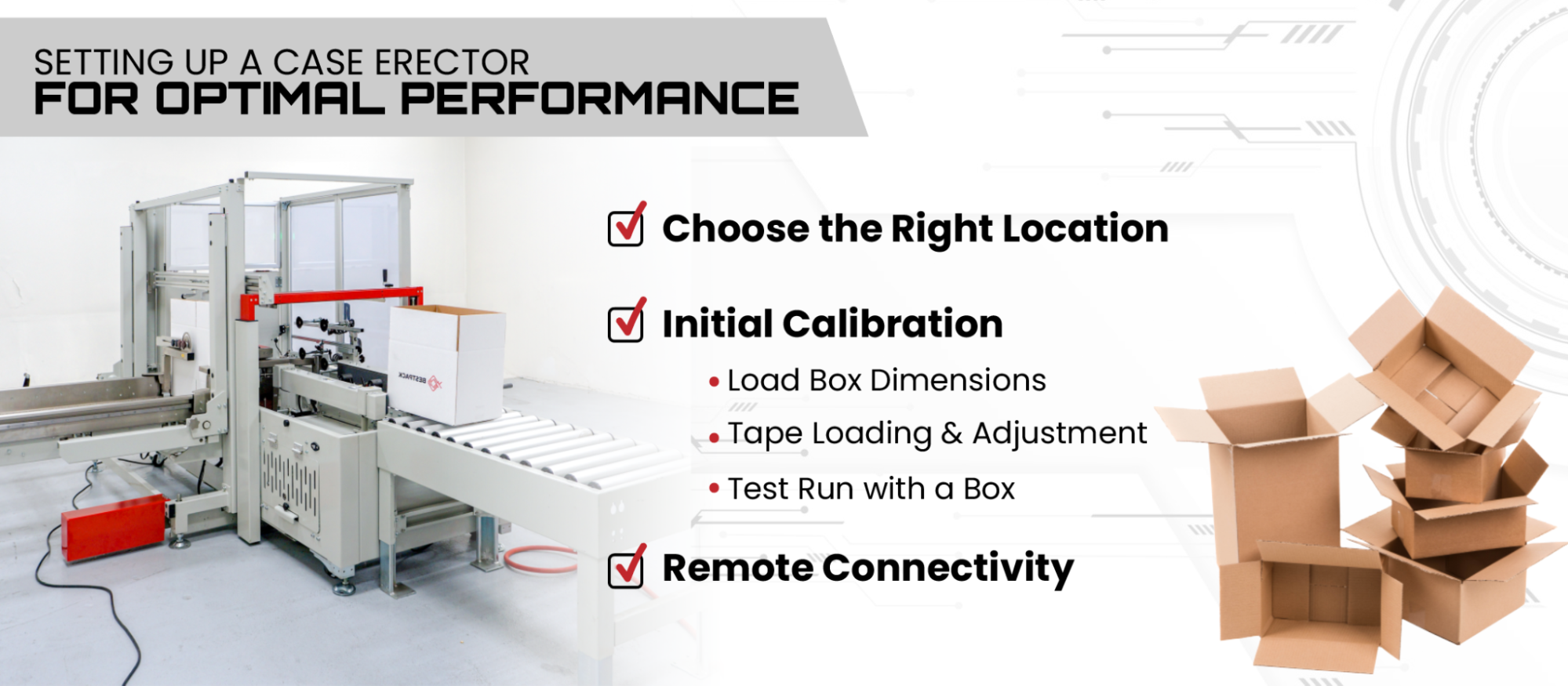

Setting Up a Case Erector for Optimal Performance

-

Choose the Right Location

- Place the case erector on a flat, stable surface close to other packaging machinery.

- Ensure the area is free of obstructions that could interfere with material loading or box transfer.

-

Initial Calibration

- Load Box Dimensions: For semi-automatic machines, manually load cartons into the hopper and adjust the machine settings to accommodate the box size.

- Tape Loading and Adjustment: Load the tape into the machine and adjust the tape head to suit the specific Carton sealing tape being used, ensuring proper application and sealing.

- Test Run with a Box: Conduct a step-by-step test run using an actual box to ensure the machine operates correctly. Verify proper airflow through the suction cups, confirm the flap folders are adjusted accurately, and check that the side belt drives are functioning as expected.

-

Remote Connectivity

- Many case erectors now come with Wi-Fi or Ethernet connectivity. Enable this to gain access to remote control features and monitoring through mobile apps or centralized systems.

- Use this connectivity to integrate the case erector with warehouse management or manufacturing systems, enhancing synchronization and tracking.

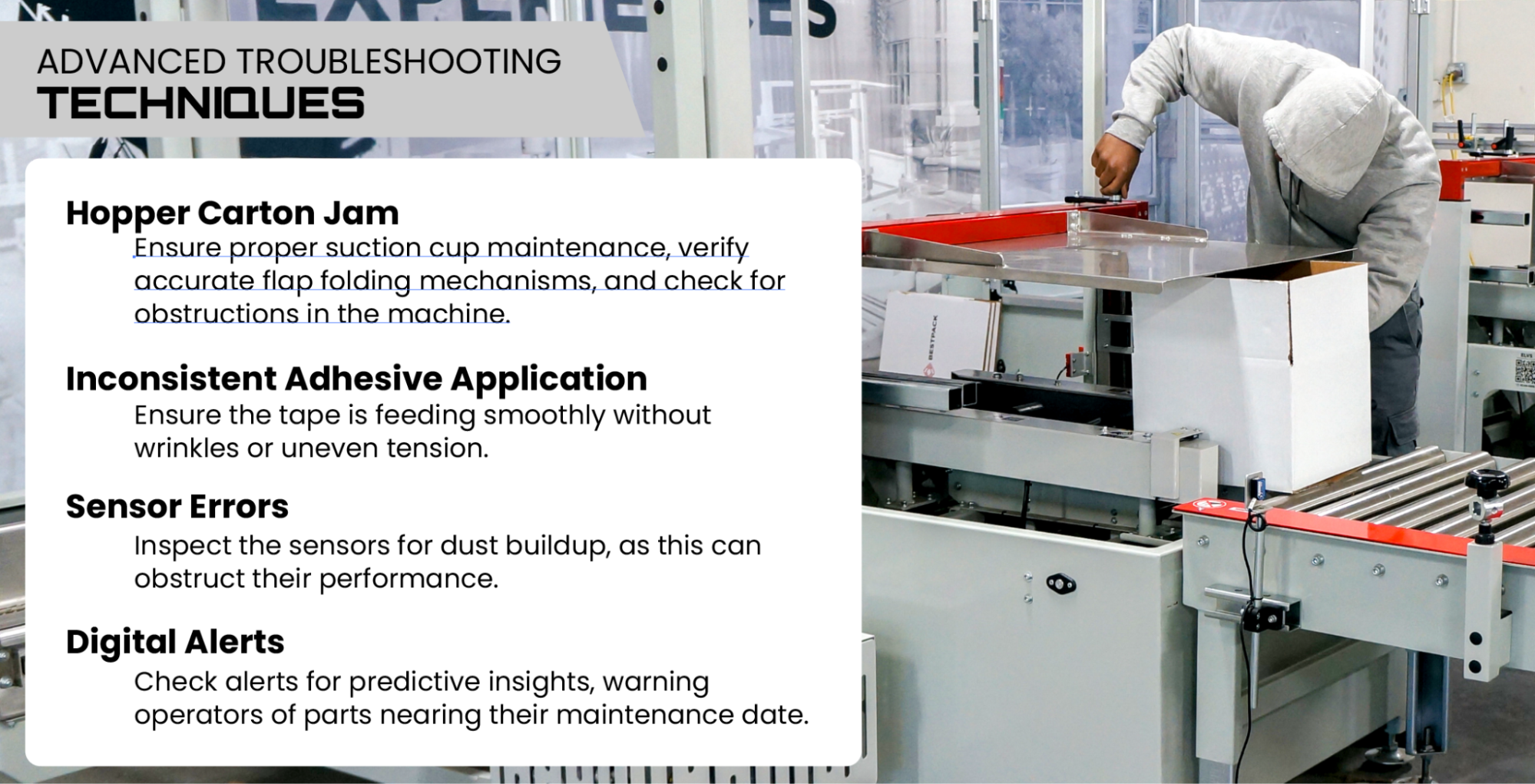

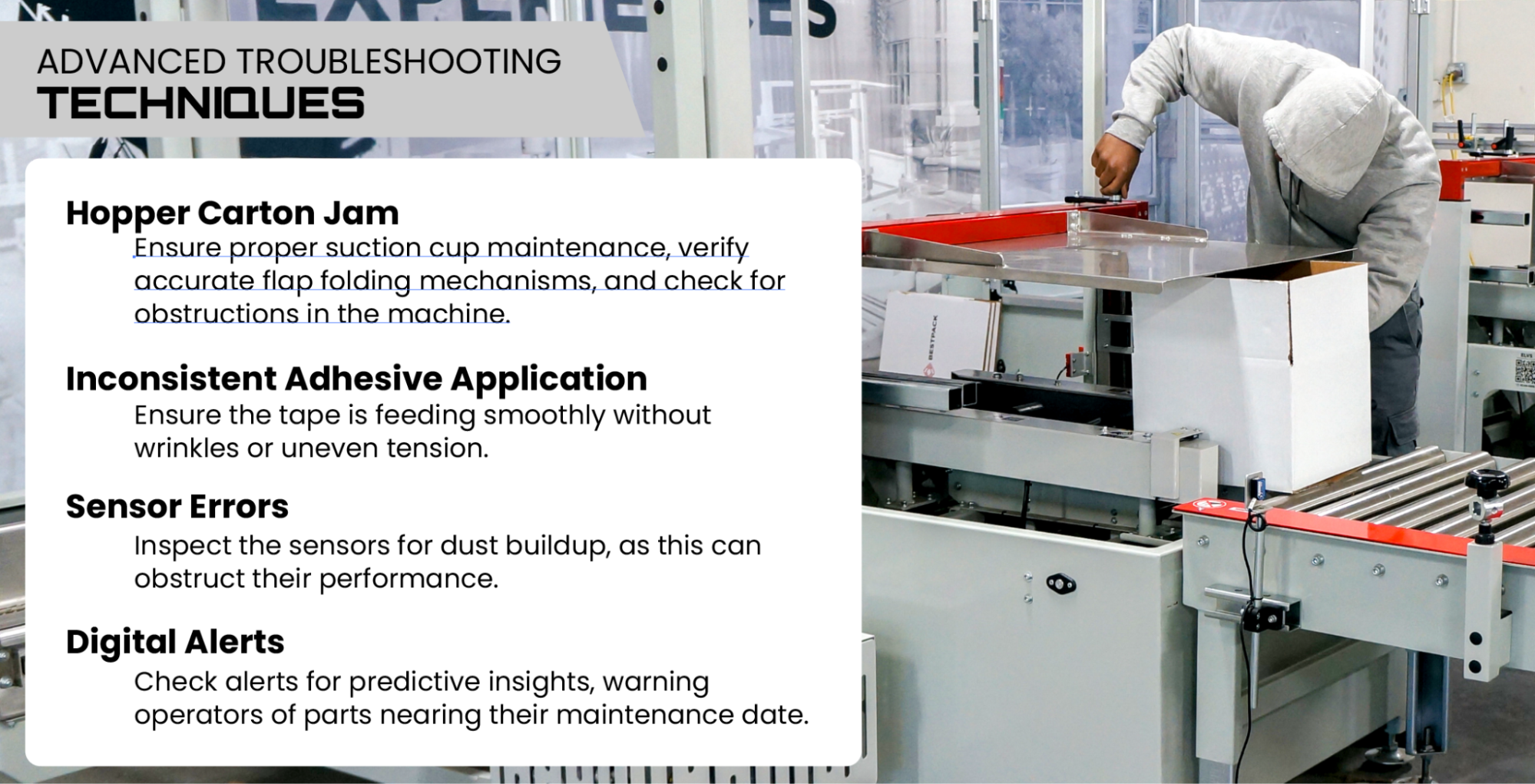

Advanced Troubleshooting Techniques

When a case erector malfunctions, having advanced troubleshooting knowledge can minimize downtime.

-

Hopper Carton Jam

- Carton jams are typically caused by suction cup failure, flap folding errors, or boxes getting stuck, rather than speed or the shape of the cartons. To address these issues, ensure proper suction cup maintenance, verify accurate flap folding mechanisms, and check for obstructions in the machine.

- Remember to stop the machine before removing any jammed cartons.

-

Inconsistent Adhesive Application

- Inspect the tape roll for proper tension and alignment. Ensure the tape is feeding smoothly without wrinkles or uneven tension. Replace the tape roll or adjust the tension settings as needed to maintain consistent sealing.

-

Sensor Errors

- Modern sensors ensure each box is correctly aligned. If you see an error code, inspect the sensors for dust buildup, as this can obstruct their performance. Align sensors properly with the reflectors in order for the machine to work..

- Conduct a test run with boxes to recalibrate the sensors and verify their positioning, ensuring proper functionality and alignment.

-

Digital Alerts

- High-tech case erectors are equipped with AI-based alert systems. These alerts can offer predictive insights, warning operators of parts nearing their maintenance date.

Customization Options for Specific Business Needs

-

Adjustable Magazine Capacity

- Select models with expandable magazine capacity to hold more boxes, especially useful for high-demand environments.

- For diverse packaging needs, consider dual-magazine machines that can handle two box sizes without reloading.

-

Integration with Robotics

- 2024’s case erectors can connect with robotic arms that transfer filled cases to palletizing areas. This automated line flow is essential for businesses handling high-volume packaging.

-

Sustainable Packaging Features

- Many case erectors now support biodegradable adhesive systems and recycled cardboard, aligning with green initiatives.

-

Real-Time Analytics and Reporting

- Some advanced systems allow users to view and export real-time operational data, enabling predictive maintenance and optimizing output by identifying bottlenecks.

Maintenance Best Practices for Modern Case Erectors

-

Scheduled Cleaning

- Conduct a detailed cleaning of sensors, adhesive applicators, and rollers monthly to maintain operational accuracy and efficiency.

- Use compressed air to clear debris from hard-to-reach areas.

-

Lubricate Moving Parts Regularly

- Regular lubrication is essential for components like folding arms and rollers. Follow manufacturer specifications for type and frequency of lubrication.

-

Replace Worn Parts

- Newer models often feature predictive maintenance, alerting users when parts are close to their wear limit. Use this data to replace belts, adhesives, and rollers before failures occur.

Benefits of Using a Case Erector in 2024

- Enhanced Efficiency and Output: Case erectors significantly boost output and reduce operational costs by reducing manual labor.

- Consistency and Quality Control: Case erectors maintain precise, uniform box formation and sealing, contributing to consistent packaging quality.

- Data-Driven Operations: Real-time data and IoT connectivity facilitate comprehensive analytics and troubleshooting, enabling faster issue resolution and optimal machine uptime.

Final Tips for Effective Case Erector Use in 2024

- Regularly Update Software: If your case erector has firmware updates, keep it current to ensure access to the latest features and security protocols.

- Training for Operators: Ensure operators are trained in basic operations and troubleshooting, maintenance, and safety practices.

By fully understanding and utilizing your case erector’s features, adhering to maintenance schedules, and leveraging automation benefits, you can streamline your packaging line and meet the high demands of modern business efficiently and cost-effectively.

Frequently Asked Questions

1. How do I monitor my case erector’s performance remotely?

Most new case erectors come equipped with Wi-Fi or Ethernet connectivity, allowing remote access to performance data. Download the corresponding app or connect the machine to your facility’s warehouse management system to track productivity, adjust settings, and receive alerts on maintenance needs.

2. How do I troubleshoot adhesive application issues?

Typically clearing up adhesive build up is to spray wd-40 on a rag and wipe down the rollers to remove build-up.

3. Are case erectors energy-efficient?

Yes, most case erectors in 2024 are designed with energy efficiency in mind. Many models enter a low-power mode when not actively in use, and components are designed to minimize power consumption during operation.

4. Can case erectors be customized for my specific packaging needs?

Yes, many case erectors offer customization options like adjustable magazine capacity, dual-magazine systems for handling different box sizes, and integration with robotics for automated line transfer. Contact your manufacturer to explore the customization features that fit your operation.

5. How often should I update my case erector’s software?

If your case erector supports firmware updates, keep it updated to ensure access to the latest features, security patches, and optimizations. Regular updates will improve machine performance and may introduce new functionality.