L-Bar Sealers: Effective Shrink Systems to Increase Product Security

Why Buy an L-Bar Sealer?

- L-Bar Sealers are crucial in logistics and warehousing operations, providing efficient and secure packaging solutions. These machines are designed to quickly and effectively seal products in shrink film, protecting them during transportation and storage.

- L-Bar sealers are indispensable tools providing efficient and effective solutions for sealing various products in shrink film. These machines are named for their distinctive “L” shaped sealing bars, which swiftly and precisely seal shrink films around items, creating secure and professional-looking packages.

- L-bar sealers are versatile packaging machines designed to seal products in shrink film efficiently and securely. They feature two sealing bars arranged in an “L’ shape, which move to create precise seals along the edges of the products. BPX Solutions offers 2 different types – Semi-Automatic L-Bar Sealers and Fully Automatic L-Bar Sealers. Our Semi-Automatic L-bar sealers automate the sealing process to a certain extent. These models typically have a push-button operation, allowing the user to initiate sealing while positioning the product and film, which is ideal for medium- to high-volume packaging tasks. Fully automatic L-bar sealers offer a completely automated operation, with integrated conveyor systems that feed products into the sealing area. They are capable of high-speed packaging and are suitable for large-scale production environments where efficiency and throughput are needed.

What is an L-Bar Sealer?

- An L-Bar Sealer is a packaging machine that seals products in shrink film. It’s named for it’s distinctive “L” shaped sealing bars, which move to create precise seals along the edges of the product. This results in a tightly sealed package that protects the product during transportation and storage.

- L-bar sealers are essential tools in packaging operations. They offer efficiency, precision, and reliability in sealing products in shrink film.

- L-Bar sealers offer several benefits in packaging operations, including efficiency, versatility, product protection, professional presentation, space optimization, and security.

Types of L-Bar Sealers

-

Semi-Automatic L-Bar Sealers

Semi-automatic L-bar sealers offer efficient sealing, adjustable parameters such as time and temperature to accommodate different packaging requirements, a compact design, medium—to high-volume capacity, and user-friendly operation. The advantages of a semi-automatic L-bar sealer are efficiency, productivity, ease of use, flexibility, and cost-effectiveness.

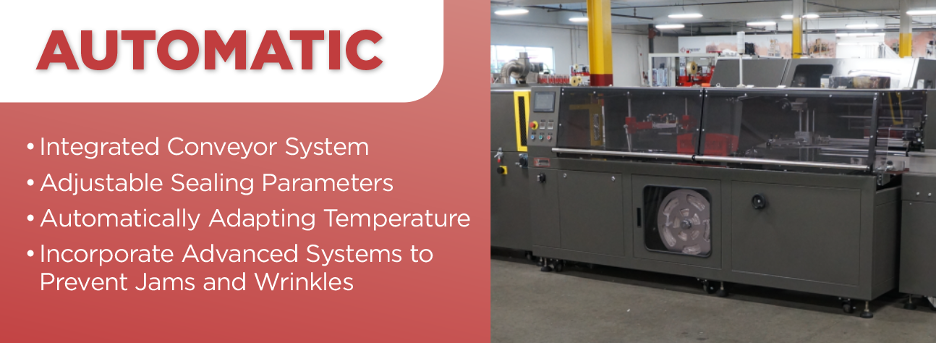

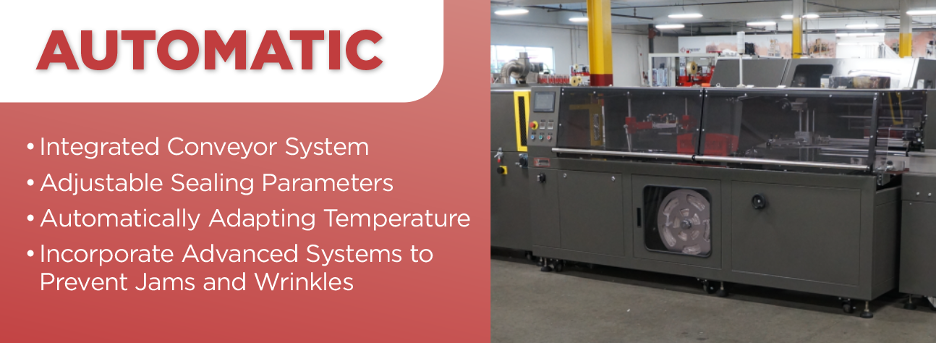

The automatic L-bar sealer features an integrated conveyor system that effortlessly feeds products into the sealing mechanism. Once positioned correctly, this sealing mechanism automatically seals the product, ensuring consistent and reliable results every time. Our automatic L-bar sealers boast adjustable sealing parameters, automatically adapting temperature, sealing time, and pressure settings to suit the specific requirements of shrink-wrapped products.

Additionally, these sealers incorporate advanced systems for handling shrink film, including film unwind mechanisms and tension controls, which prevent jams and wrinkles before the product enters the shrink tunnel.

Fully automatic L-bar sealers offer maximum efficiency and automation but incur a higher upfront cost. Semi-automatic sealers provide a balance between automation and affordability, making them suitable for businesses with medium to high-volume packaging needs seeking to improve efficiency without making a significant investment in automation.

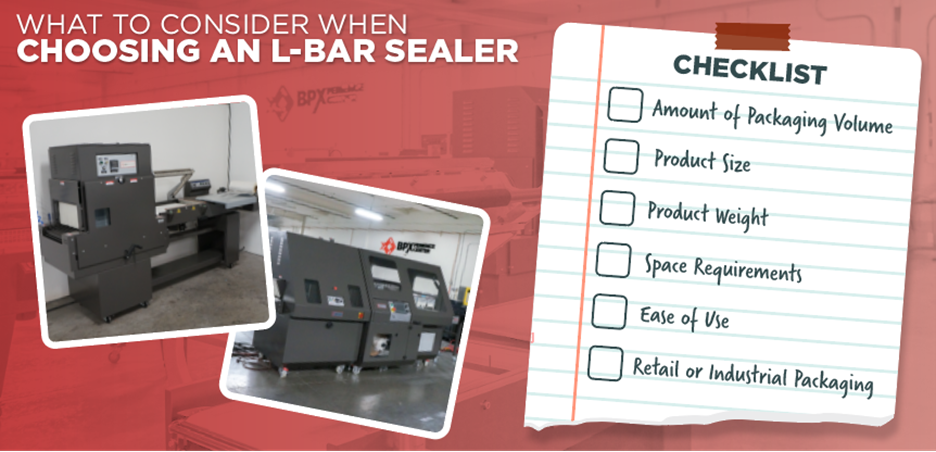

What to Consider When Choosing a L-Bar Sealer

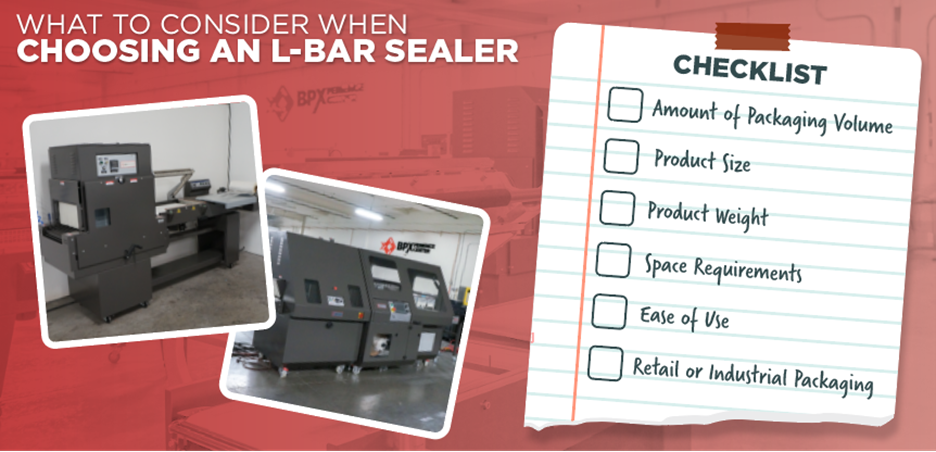

- Things to consider before choosing an L-Bar Sealer are the amount of Packaging Volume, Product Size and shape, Product Weight, Space Requirements, Ease of use, and whether this is retail or industrial packaging (to determine the right packaging material to use).

- If you operate a small business with low to moderate packaging volumes a semi-automatic L-Bar sealer is sufficient, typically they are more affordable and require less space, making them suitable for smaller operations with limited resources. We recommend using a fully automatic L-Bar sealer for medium to larger businesses with higher packaging volumes. These machines provide greater efficiency and throughput, helping to streamline your packaging operations and meet increased demand. What’s most important when choosing an L-Bar sealer is understanding your anticipated growth, considering your business’s growth projections, and whether the L-Bar Sealer can scale with your evolving needs. BPX Solutions offers a variety of flexible L-Bar sealers that can be upgraded to accommodate increased packaging volumes as your product specifications change over time.

How Do You Use an L-Bar Sealer

Due to the number of L-Bar Sealers we offer, we’ll guide you through using a simple semi-automatic L-Bar Sealer.

- Preparation:

- Ensure the L-Bar Sealer is plugged in and in a well-ventilated area.

- Make sure Quick Shrink Film is added to the film roll.

- Turn on the L-Bar Sealer so the blades get heated.

- Adjust Settings:

- Adjust the sealing time and conveyor speed settings and configure them according to your product size.

- Shrink Film and Loading Products:

- Place the products on the loading tray

- Unroll a sheet of shrink film from the roller and position it over the product to ensure adequate coverage on all sides.

- Move the product into the sealing area

- Lower the Sealing Bar:

- Use the Push-Button control mechanism to lower the sealing bars to start the sealing process.

- Heat Sealing (if connected to shrink tunnel):

- The L-bar sealer is equipped with an automated conveyor that automatically moves your product into a shrink tunnel’s rolling conveyor.

- Repeat process

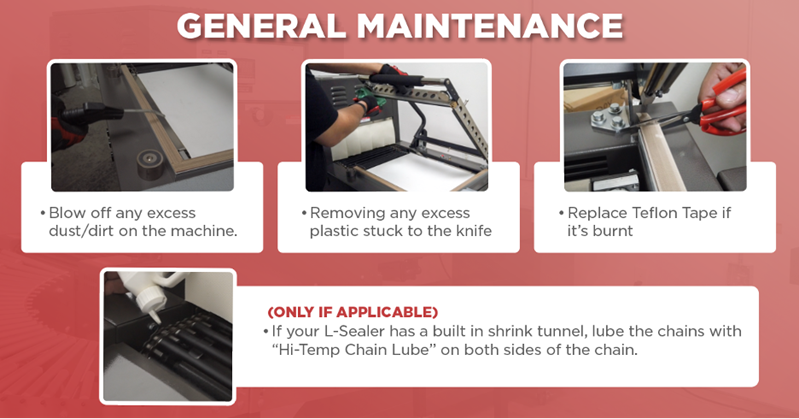

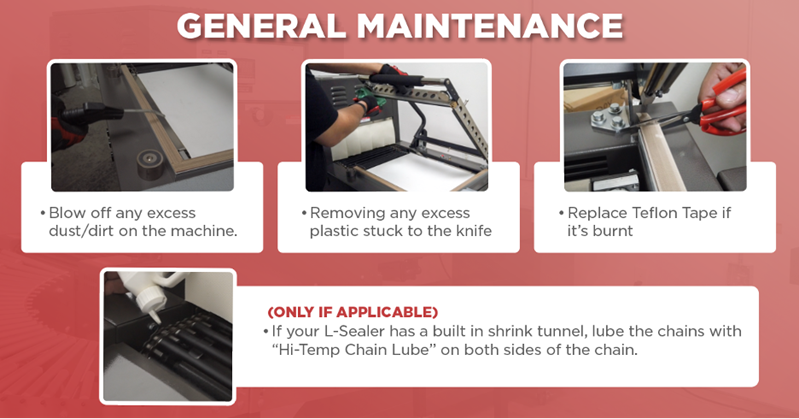

General maintenance tips to keep your L-bar sealer lasting a long time:

- Blow off any excess dust/dirt on the machine.

- Wear protective gloves, heat the micro knife, and wipe it down, removing any excess plastic stuck to it.

- Replace Teflon Tape if it’s burnt.

- (Only if applicable) If your L-Sealer has a built-in shrink tunnel, lube the chains with “Hi-Temp Chain Lube” on both sides of the chain.

Conclusion

Choosing the suitable L-bar Sealer should be based on the following reasons: How the L-bar sealer can significantly improve the efficiency of your packaging operations. Choosing an L-bar sealer for its versatility and adjustability to seal a wide range of product sizes and shapes allows you to scale up as you grow your operations. A return on your investment over time and the long-term cost savings you’ll get when you implement a solution into your packaging line.