Is it just us or did 2018 go by way too fast? Feels like yesterday, watching the New Years fireworks overhead. And yet here we are, days away from 2019. That is precisely what we wanted to discuss with you.

E-commerce continues moving toward becoming the most popular shopping medium as each month goes by. In September 2018 e-commerce expanded by 11.4%. Today, since nearly all brands have a solid online presence, companies have been looking for ways to differentiate and get a leg-up on competition. Often times this falls into having extremely fast turn around on their shipping time frames and costs.

A study conducted recently has found that in 2012 people were willing to wait an average of 5.5 days for free shipping. Whereas now, that same study found that people are willing to wait only 4.5 days on average. Programs like Amazon Prime have made two-day shipping the standard, so cutting down on shipping time is vital for any e-commerce business looking to stay afloat.

Most importantly, this trend is definitely going to continue throughout 2019 as brands look for new ways to differentiate themselves from an increasingly saturated crowd through packaging & shipping.

Now the real question is: how can you best prepare your business for this upcoming year and improve your packaging and shipping lines to best compete?

BestPack is the leading solution provider in the packaging industry and as such has fully customizable automatic and semi-automatic machines designed to fit your packaging line and increase your businesses efficiency and professionalism, saving you money over time.

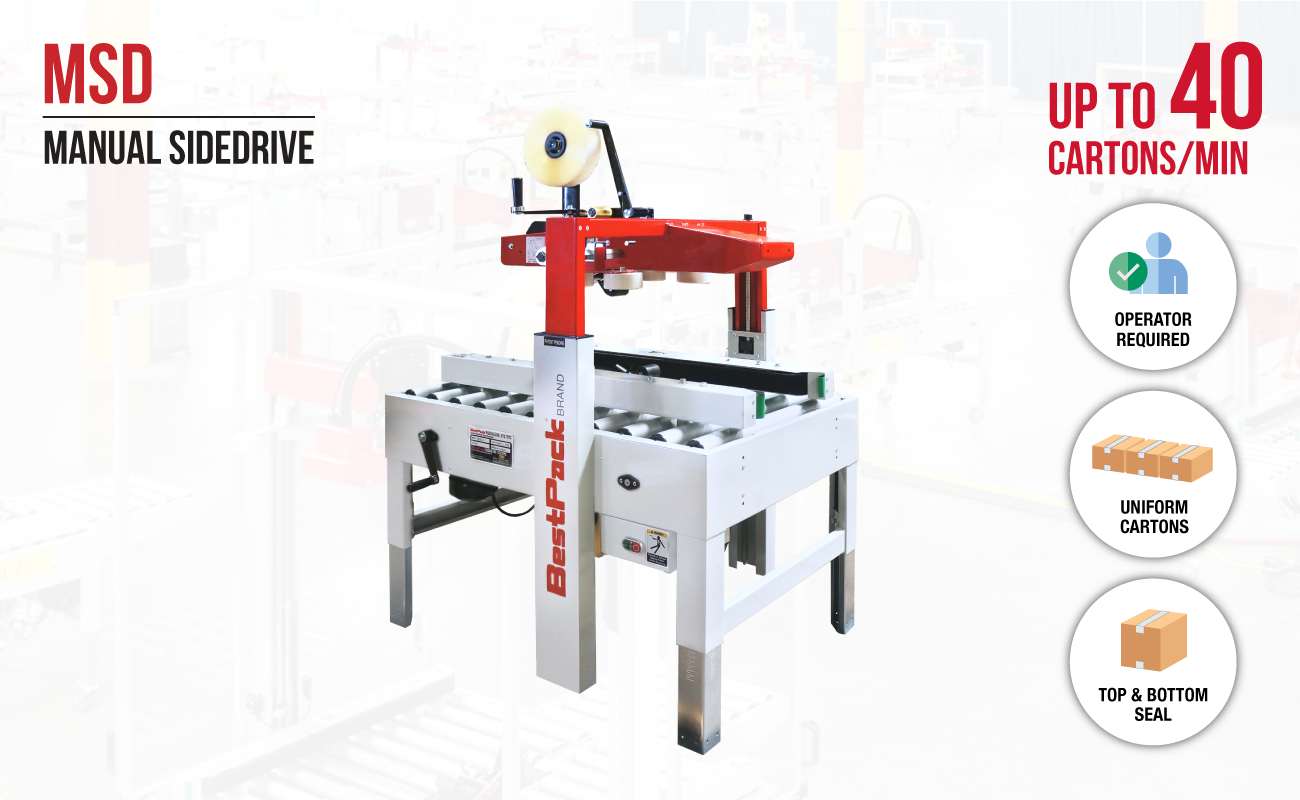

Basic Automation – When it comes to putting in place basic automation for your packaging line, we have the exact machines for you. As an example is our MSD, the BestPack MSD Series is a Semi-Automatic Uniform Tape Carton Sealer and is our most popular operator-fed adjustable carton sealer. The MSD is a top of the line machine, designed to suit a variety of light-to-heavy duty uniform carton closure applications. Using side belt technology, the MSD will seal very narrow to wide cartons.

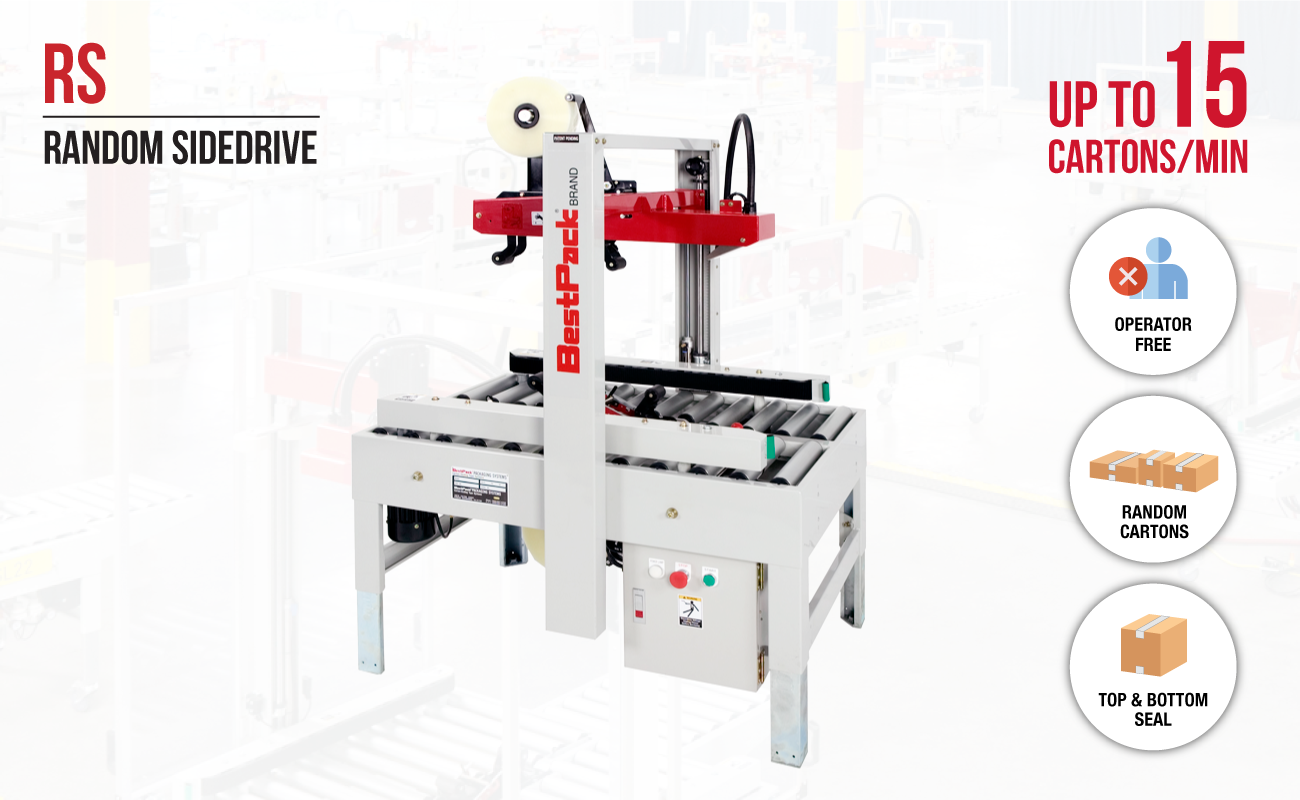

Mid-Tier Automation – Now if your packaging line needs a boost or you want to jump straight to mid level in packaging automation, our RS sealer is for you. The BestPack RS is a Semi-Automatic Random Tape Carton Sealer that easily seals a wide range of random carton weights and sizes, with masts that allow for an extra 4″ of carton height on the upper assembly. The RS Series is built for speed and rugged dependability. Using side belt drives, the RS is bble to effectively seal very light to very heavy cartons, BestPack’s RS sealer is a workhorse and the most flexible unit in our random carton sealer product line. it’s an excellent solution for your fulfillment warehouse.

Fully Automatic Systems – Looking for arguably the best bang for your buck while putting in place a customizable but completely automatic packaging system? Our BestPack ELVS & CSS machines are designed to work seamlessly together to create a completely automated packaging line for your fulfillment warehouse.

Our ELVS is a high speed uniform carton erector with one of the smallest footprints in the market today and can be customized to fit into any packaging line. This machine can erect 10-15 cartons per minute and doesn’t require an operator to run the machine.

Our CSS is a Fully Automatic Random Carton Sealer featuring our servo driven technology, which allows for fast height adjustment, quick width adjustment and smooth sealing operations. The CSS’ design utilizes three independent stations: centering station, flap folding station, and sealing station. The CSS is designed for speed and allows for precise positioning at each station. This machine is capable of a carton output up to 30 cartons per minute.

It’s safe to say that our machinery will get you the best results for your money. Not just as a great tax write-off for 2018 but also as a solid investment into automating your packaging line or enhancing your existing packaging line coming into 2019.

Reach out to us today and let us help you put that future together. Click Here