Shrink Wrap Machine: What It Is and How to Use It

Efficiency and protection are paramount in packaging. A shrink wrap machine, a staple in various industries, embodies these qualities by providing a means to quickly and securely wrap products in a protective plastic film. Let us explore what shrink wrap machines are, the different types available, how they operate, and practical tips for their use.

What is a Shrink Wrap Machine?

A shrink wrap machine is a device that encloses or wraps products in a transparent, plastic film that is then subjected to heat. The heat causes the film to shrink tightly over whatever it is covering. This process secures the product and protects against dirt, moisture, and tampering. The result is a clean, attractive packaging solution widely used in numerous sectors, including food and beverage, electronics, publishing, and pharmaceuticals.

How to Use a Shrink Wrap Machine?

Setup and Preparation

- Choose the Right Film: Options include PVC, polyolefin, and polyethylene, each with different characteristics suitable for various products and durability needs. An additional tip, QUICK SHRINK-IR or QUICK SHRINK-201, may help ensure that you choose the right film for your shrink-wrap machine.

- Set Up the Machine: Install the film roll and thread it through the machine according to the manufacturer’s instructions. Adjust the sealer and heat tunnel temperature settings based on the film type and product size.

Operating Process

- Product Placement: Place the product in the center of the film sheet. For manual machines, wrap the film around the product and seal it using the sealer bar.

- Sealing: For automatic machines, the product with the film automatically moves into the sealing area, where the machine cuts and seals the film.

- Shrinking: The sealed product then passes through the heat tunnel, where the film shrinks tightly around it.

- Quality Check: After the product exits the machine, check for consistent sealing and the absence of wrinkles or loose ends.

Types of Shrink Wrap Machines

Shrink wrap machines come in various forms, each designed to meet specific needs:

- Manual Shrink Wrap Machines: These are hand-operated. The operator wraps the product with film and manually moves it to a heat source to shrink the wrap.

- Semi-Automatic Shrink Wrap Machines: The operator must still place the products in the film. However, the process of sealing and shrinking the film is automated.

- Fully Automatic Shrink Wrap Machines: These machines handle the entire process from product insertion, film wrapping, sealing, and shrinking without human intervention, suitable for high-volume packaging operations.

Components of a Shrink Wrap Machine

- Sealer: This part of the machine cuts and seals the film around the product. Sealers vary depending on the type of machine, ranging from manual bars to automated arms.

- Heat Tunnel: After sealing, the product passes through a heat tunnel where hot air or radiant heat shrinks the film tightly around the product.

- Conveyor System: Particularly in semi-automatic and automatic machines, a conveyor system moves the product through the machine.

What is the Size of a Shrink Wrap Machine?

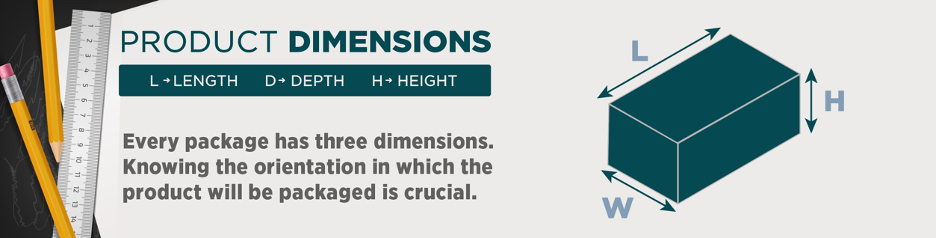

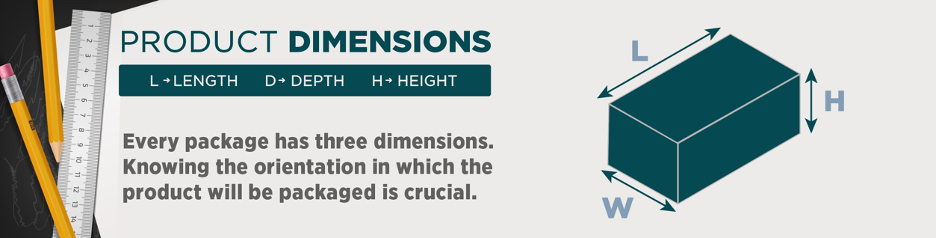

The second most critical aspect to consider when selecting the appropriate shrink-wrapping machine is the minimum and maximum dimensions of the products you will be wrapping. Every package has three dimensions: width, length, and height. Additionally, knowing the orientation in which the product will be packaged.

Shrink wrapping machines are constrained by the maximum size of the items they can encase. For manual or semi-automatic L-Sealer models, this maximum is determined by the dimensions of the L bar.

Fully automatic models, on the other hand, do not restrict the length of the product, but there are still mechanical limits on the height and width.

Choosing a shrink wrapper of the appropriate size is crucial for minimizing packaging costs and maximizing production efficiency. Ensuring that the shrink wrapper and the heat tunnel are large enough to handle your most significant product is essential.

What Shrink Wrap Machine Offers?

What is your product? Whatever that may be, here are some typical results to expect from a shrink-wrap machine:

- Display: Notice the shiny outer packaging among other products while protecting the primary packaging. For an additional advantage in branding, also use a printed film.

- Tamper-Resistance: The packaging is proof of the end-user’s first usage. End-users gain confidence in buying the product with an unopened shrink wrap.

- Protection: During transport, water, dust, or any unwanted external material/factors on the product ensures a fully closed shrink wrap that protects the product.

- Storage/Logistics: To create an easy-to-carry package for heavy items.

- Bundle of Products: It can shrink and wrap group products for multiple purposes. For your convenience, it can also provide results with an opening on the sides of the package when your product is heavy and you need to carry it by hand easily.

More Flexible Film Wrapping Equipment

To understand what equipment to use in the packaging world. Here are some ideas for flexible film-wrapping equipment:

- L-Bar Sealers: BestPack provides the best range of L-Bars available. These include their budget-friendly All-in-One Sealer/Shrink Chamber, the affordable 1519 series, the robust 1622 Series available with different cutting options, various models of their Automatic L-Sealer, and several types of faster side sealers.

- Side Sealers: These wrappers encapsulate products in a continuous tube of film, sealing along one side of the package and then separating them into individual units downstream using a cross seal. Unlike L-bar sealers, side seal machines can run random products of infinite length.

- Shrink Tunnels: A shrink or heat tunnel is a heated tunnel mounted over or around a conveyor system. Items (such as packaging) have shrink film loosely applied; with heat, the film shrinks to fit snugly around the wrapped object. BPX provides a wide range of shrink tunnels, from small 110v models to the largest, most durable ones available. They come in many sizes, with different conveyor styles and voltages, and include easy-to-use features.

- Flow Wrappers: Flow wrapping helps keep your raw materials safe and protected. It tightly wraps the packaging around the product to prevent it from moving too much and getting damaged. The wrapping uses just enough material to seal the package, avoiding excess that would hang off the ends.

- Poly Bundlers: Poly bundling is a method to group items of the same size into packs, which can be wrapped with either transparent or printed film. Printed film needs special plates and designs to create. All bundles have openings at each end called “bulls eyes” due to their oval shape. Now, Poly Bundlers have become more accessible and affordable. They are also being offered hand-fed, belted or right-angle automatic feeding.

Maintenance Tips

- Regular Cleaning: Keep the machine clean from dust and film residues, which can affect its performance and the quality of the seal.

- Periodic Checks: Regularly inspect the sealing bar and heat tunnel to ensure they function correctly and efficiently.

- Lubrication: Depending on the model, some parts may require lubrication to maintain smooth operation.

Conclusion

A shrink wrap machine is an invaluable tool in modern packaging, offering an efficient method to protect and enhance the appearance of products. By understanding the different types of machines and their components and how to use them effectively, businesses can ensure their products are presented in the best possible manner, with safety and cleanliness guaranteed. Mastering a shrink wrap machine can significantly impact productivity and product presentation for small-scale operations or large industrial environments.