When managing a packaging line, many businesses naturally look for ways to cut costs. A common approach is to shop around for equipment and consumables from multiple suppliers to secure the best price for each component.

However, this strategy often leads to unforeseen complications—such as compatibility issues, where machines from different manufacturers can’t communicate seamlessly—reducing overall efficiency, increasing downtime, and driving up costs.

Here’s why relying on multiple suppliers may not be as cost-effective as it appears and why an integrated approach with a single vendor is often the smarter choice.

At first, sourcing various components of your packaging system from multiple vendors may seem practical. You might find a competitive price on a sealer from one supplier, cartons from another, and tape from yet another. But as these pieces come together, several issues tend to arise.

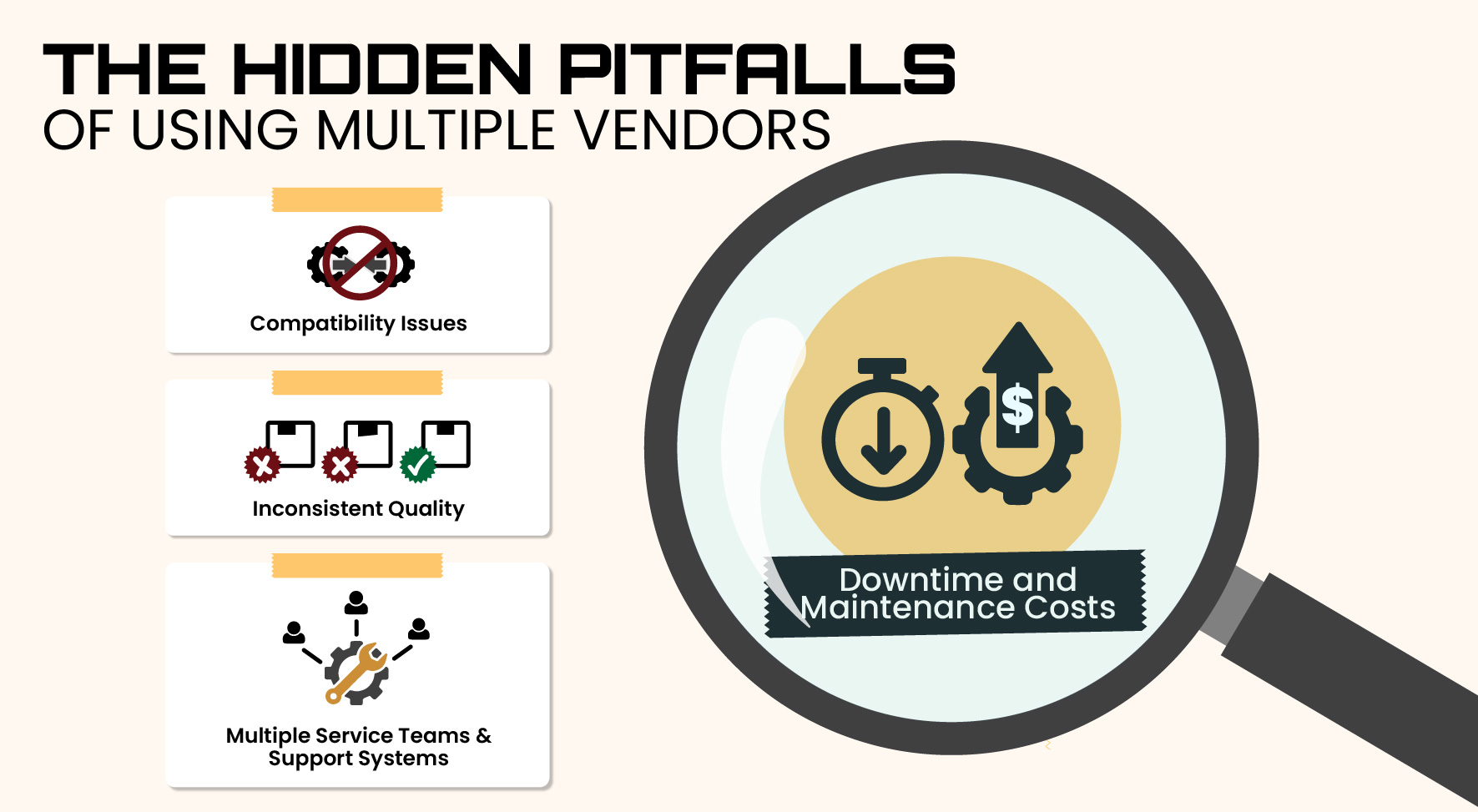

Equipment and consumables from different suppliers aren’t always designed to work in sync. Not only are they often incompatible, but different manufacturers also use unique programming and settings, making it difficult for these machines to communicate.

Even minor incompatibilities can lead to inefficiencies, such as poorly sealed boxes, slower production rates, and an increased need for manual adjustments, higher maintenance, and unplanned downtime.

A major drawback of sourcing from multiple suppliers is the inconsistency in quality across equipment and consumables.

While you may save on initial purchases, poor-quality products can lead to higher failure rates, frequent malfunctions, and costlier repairs. Over time, these costs accumulate, often outweighing any initial savings.

Managing various warranties and service agreements is one of the biggest challenges with multiple suppliers. When equipment malfunctions, it can be challenging to determine who is responsible for the repair, often leading to delays and downtime as vendors point fingers at each other.

When your equipment and consumables don’t work together seamlessly, the likelihood of downtime significantly increases. Coordinating maintenance across multiple vendors quickly becomes a logistical challenge, further increasing downtime and maintenance costs.

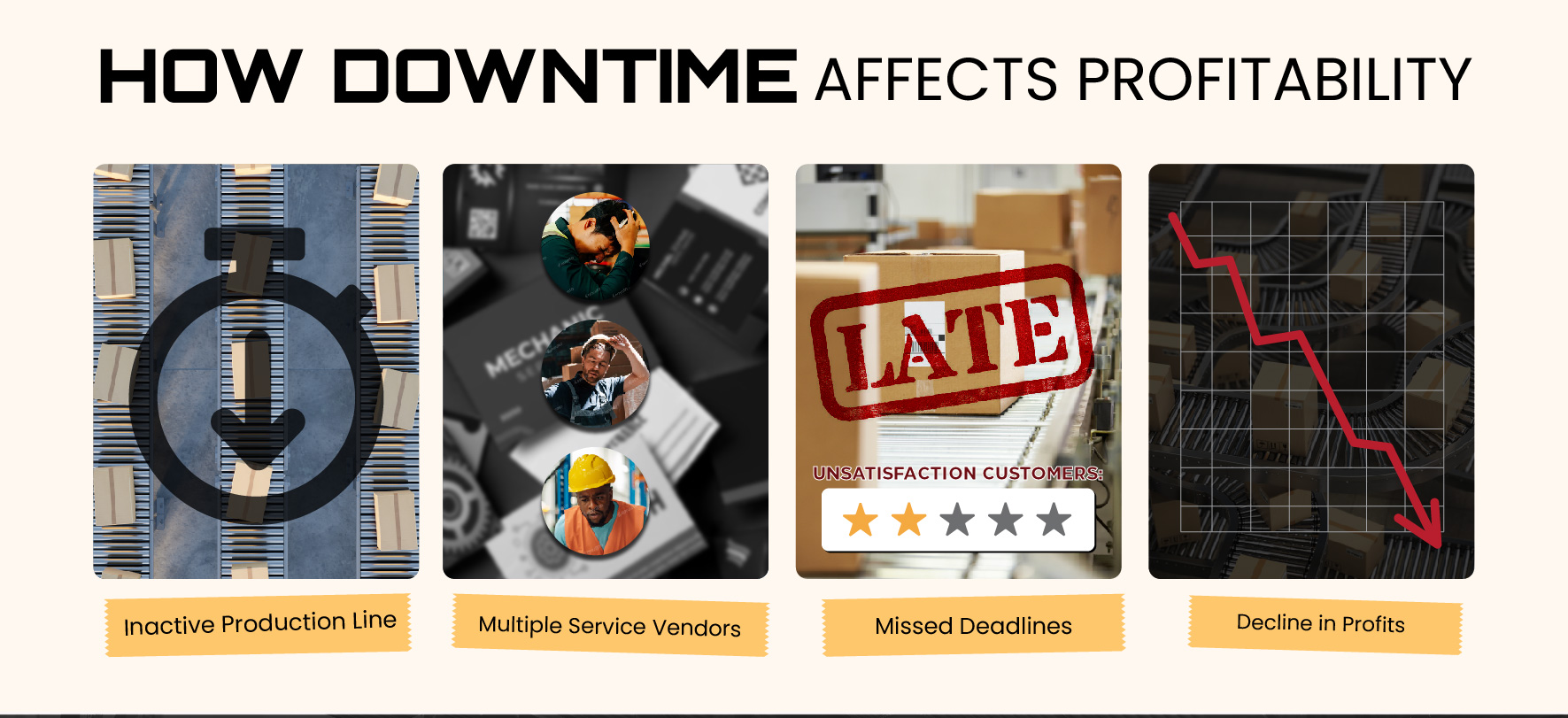

Downtime is one of the biggest threats to profitability in packaging. Each time a machine goes offline, the impact on productivity and revenue is immediate. For companies with tight schedules, even small interruptions can lead to missed deadlines, unhappy customers, and ultimately, lost business.

With multiple vendors, these disruptions are more likely and harder to resolve. Fragmented systems often mean slower repair times, as you’re forced to navigate varying service agreements and depend on multiple vendors who may not prioritize seamless integration.

The result? Increased downtime and ongoing issues that drain resources.

To avoid these challenges, many companies turn to a single-vendor approach. By purchasing all equipment and consumables from a single source, you can eliminate compatibility issues, streamline maintenance and repairs, and significantly improve operational efficiency.

Here’s why a unified system can make all the difference:

When all components of your packaging line come from the same supplier, they’re designed to work together perfectly.

This seamless integration reduces compatibility issues, enhances performance, and provides consistent output. A cohesive unit also means fewer interruptions in your production line, improving overall reliability.

One Service Team for Everything

A single service team that understands every aspect of your system makes repairs and maintenance much simpler.

There’s no back-and-forth between vendors, no confusion about warranties, and no delays. When issues arise, you know exactly who to contact, and the support team knows how to solve the problem efficiently.

Consistent Quality Across Products

Sourcing all your equipment and consumables from one vendor ensures consistent quality across the board. This consistency improves system reliability and reduces the need for repairs and frequent maintenance. Over time, it translates into lower maintenance costs and minimized downtime.

While a unified system may appear to have a higher upfront cost, the long-term savings are substantial.

A system with fewer repairs, less downtime, and optimized operations provides a better return on investment. Additionally, you avoid the hidden costs associated with low-quality consumables and the hassle of multiple service agreements.

Now that we’ve explored the benefits of working with a single vendor, let’s look at how BestPack can provide the unified solution your business needs.

With over 35 years of experience, BestPack specializes in complete packaging systems that streamline your operations. From carton sealers and erectors to high-quality tape and shrink film, BestPack offers everything needed to maintain a reliable packaging line.

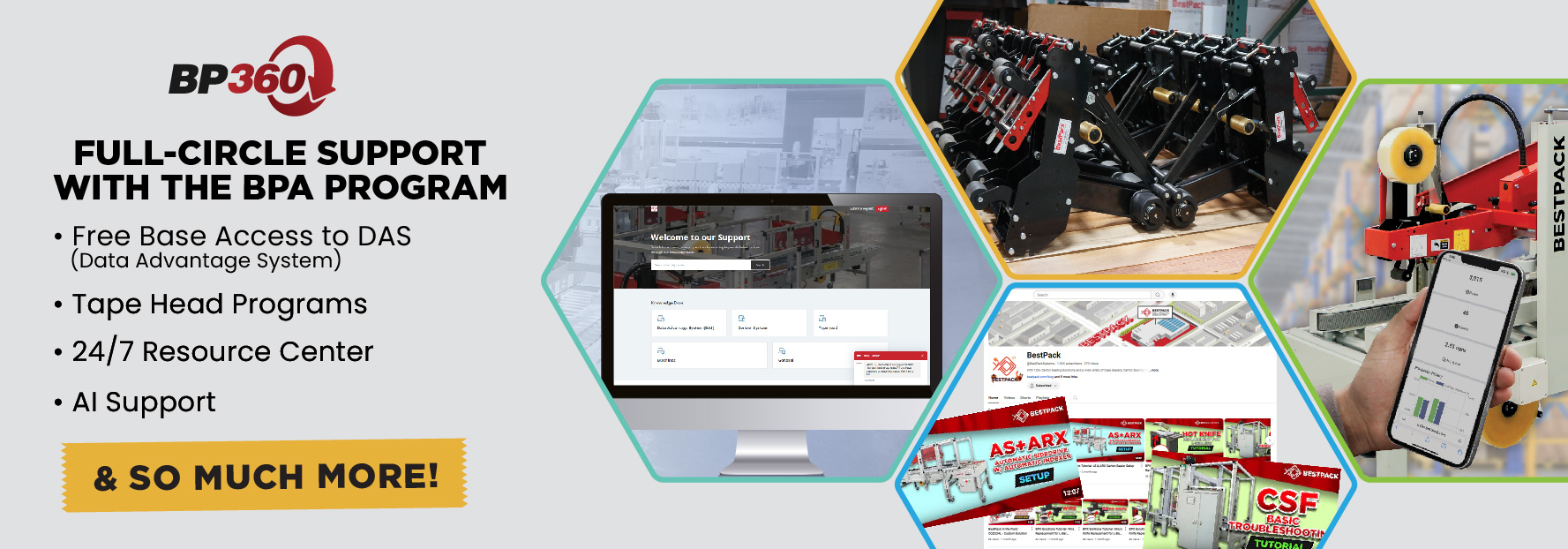

BestPack’s BP360 Program is a comprehensive support solution that covers every part of your packaging system, including our BPA Program. This full-circle program ensures your packaging line remains at peak performance, minimizing downtime and maximizing productivity. Here are just some of the major support features:

The benefits of choosing one vendor for your packaging needs are clear.

A unified system brings greater efficiency, fewer repairs, less downtime, and ultimately, lower overall costs. BestPack’s BP360 Program, encompassing the BPA Program, offers all-encompassing support, ensuring that your operations run smoothly and allowing you to focus on what matters most—growing your business.

Ready to experience the advantages of a unified packaging approach?

Contact us today to learn more about how BestPack can help your business succeed.